Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

What should I do if frost forms on the evaporator unit?

Troubleshooting measures for frost on the evaporator unit

1. Check and adjust the refrigeration system's operating parameters

Confirm that the evaporator's inlet air temperature, humidity, and refrigerant flow rate meet design requirements.

If the refrigerant flow rate is insufficient or the evaporating temperature is too low, increase the refrigerant pressure or adjust the set temperature appropriately to prevent frost formation caused by overcooling.

2. Clean or replace the defrost device

Check defrost systems equipped with electric heating elements, hot air circulation, or hot water circulation to ensure that the heating elements are functioning properly.

If the defrost device is aged or damaged, replace it promptly to restore defrost function.

3. Keep the evaporator surface clean

Regularly remove dust, oil, and impurities from the evaporator fins to prevent reduced heat exchange efficiency and the formation of localized frost at low temperatures.

Use a dedicated cleaning agent and a soft brush for maintenance to avoid mechanical damage to the fins.

4. Optimize the system's circulating air volume

Check the fan's operating status to ensure that the air volume is evenly distributed across the evaporator surface. If the fan speed is too low or unbalanced, repair or replacement should be performed to ensure adequate air flow and reduce the risk of frost.

How to assess the lifespan of the evaporator unit?

1. Operating Hours and Accumulated Workload

Record the cumulative operating hours of the evaporator and the operating hours under different load conditions.

Compare actual operating conditions with the manufacturer's design lifespan (e.g., 10,000 hours) to preliminarily determine the remaining lifespan.

2. Inspection of Wear and Corrosion of Key Components

Perform visual or instrumental inspection of components such as fins, piping, and seals to assess for corrosion, cracks, and deformation.

Measure the thickness of metal surfaces to determine if there is significant material loss.

3. Performance Parameter Degradation Trends

Regularly measure key evaporator indicators such as cooling efficiency, pressure drop, and air outlet temperature.

If cooling efficiency drops by more than 5% or pressure drop increases significantly, this indicates increased internal resistance and the unit's lifespan may be nearing its end.

4. Maintenance Records and Fault History Analysis

Collate past repairs, parts replacements, and fault reports to analyze fault frequency and types. Trend analysis can be used to determine if recurring problems are occurring. If so, this may indicate that the overall lifespan is about to reach a critical point.

←

What are the specific steps in the vapor compression refrigeration cycle used in household refrigerators?

→

What's the difference between an ICEMachine and a home ice maker?

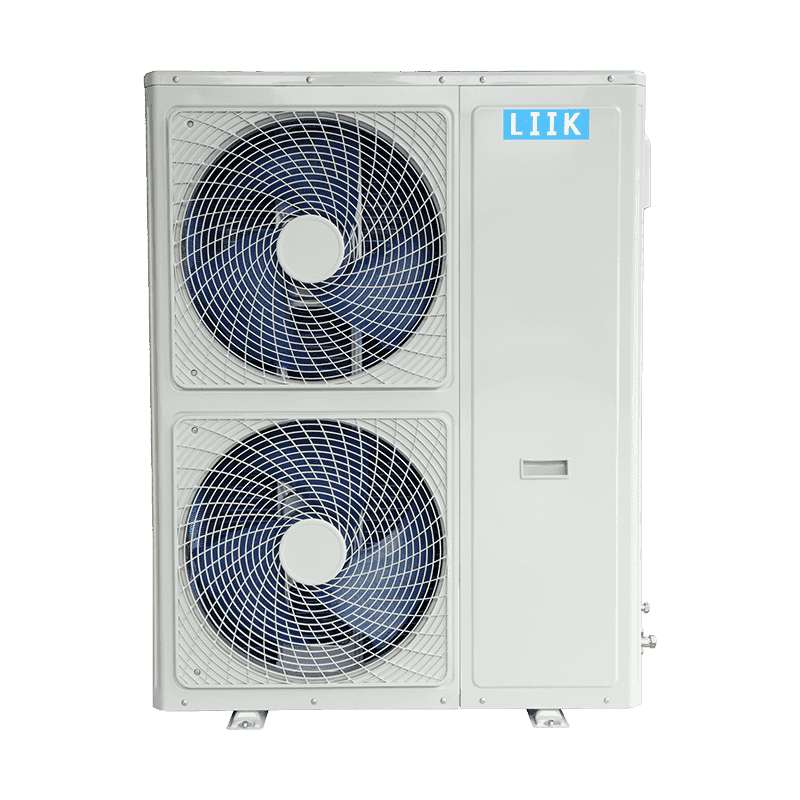

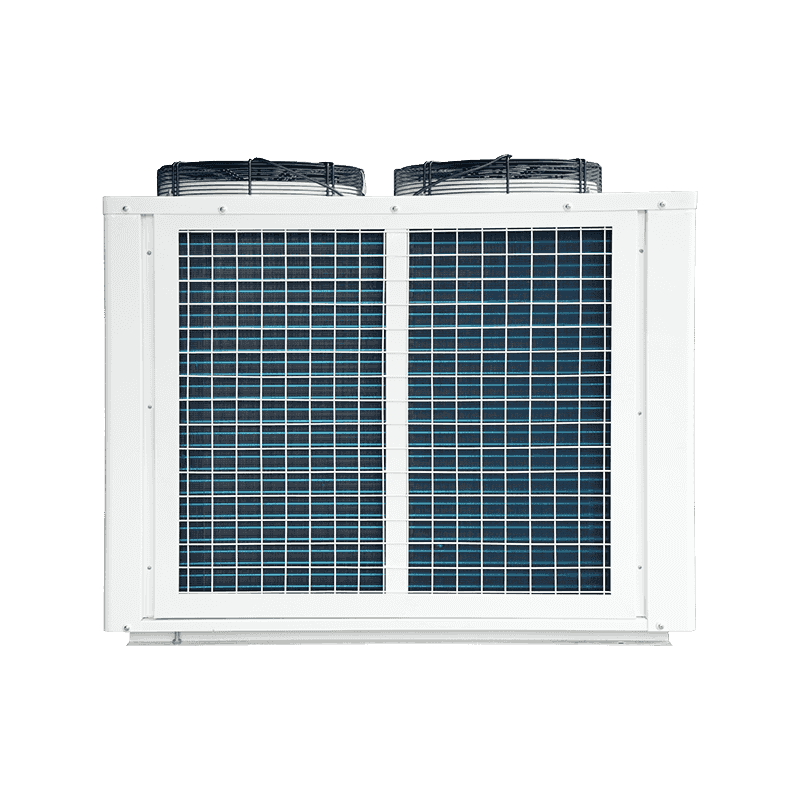

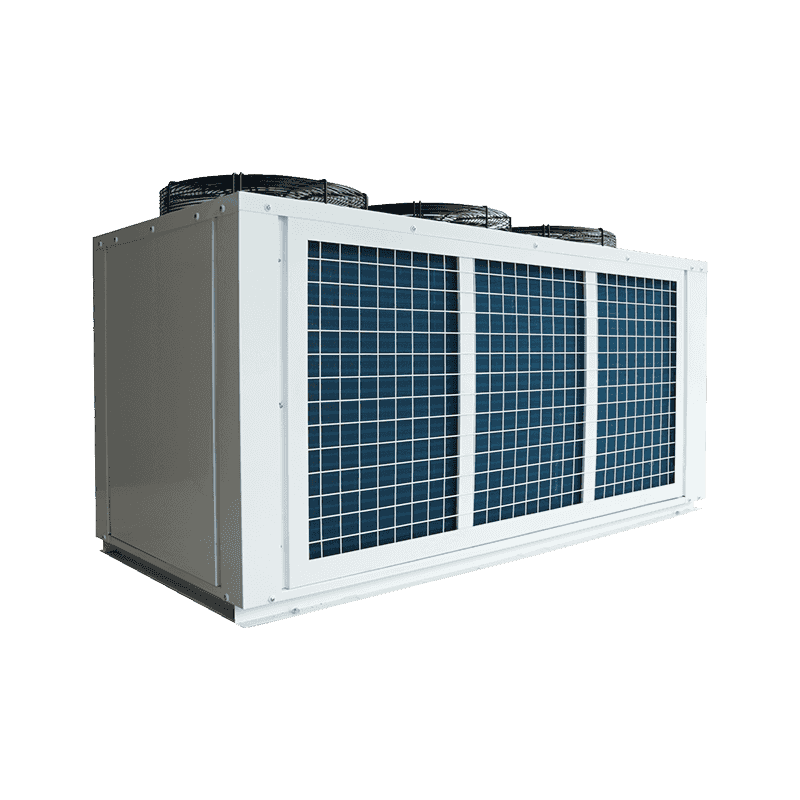

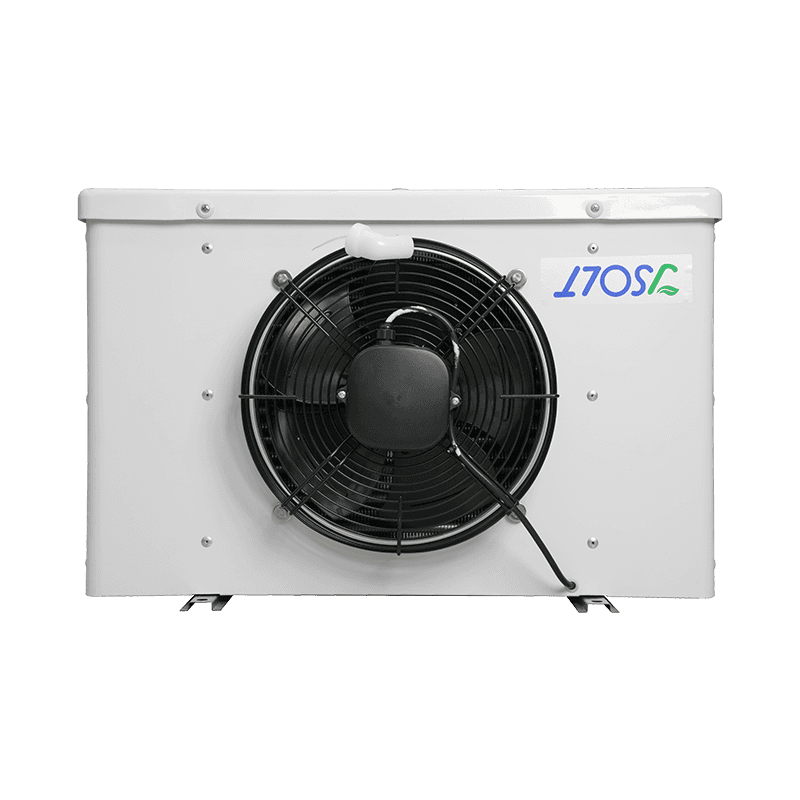

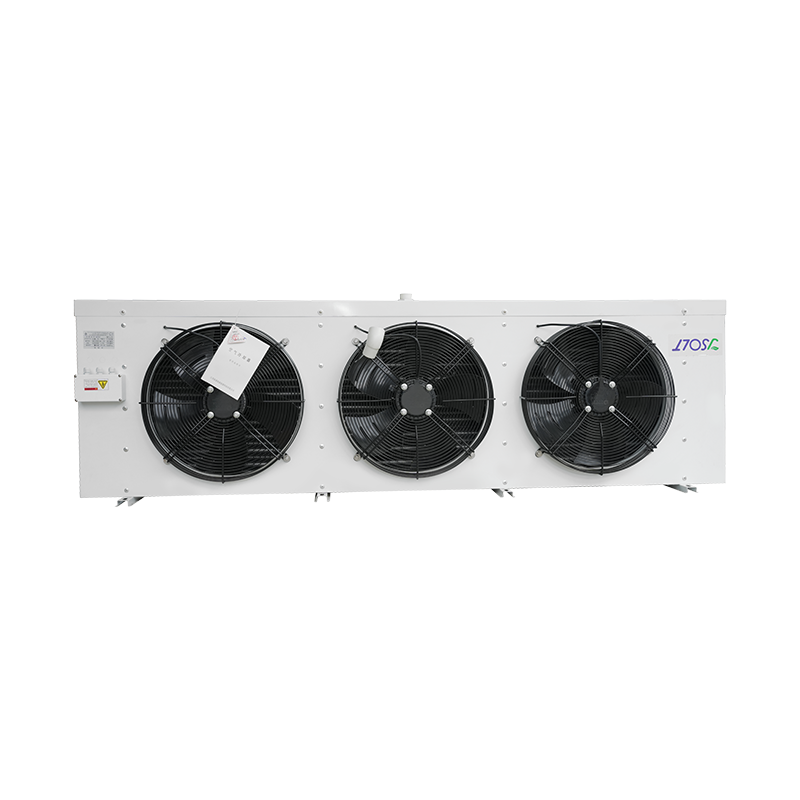

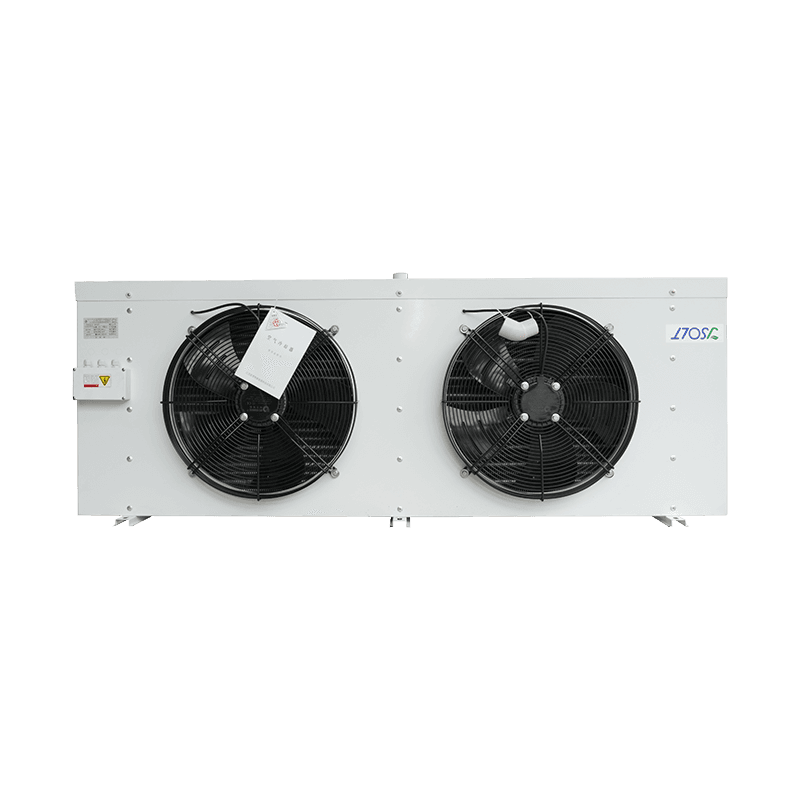

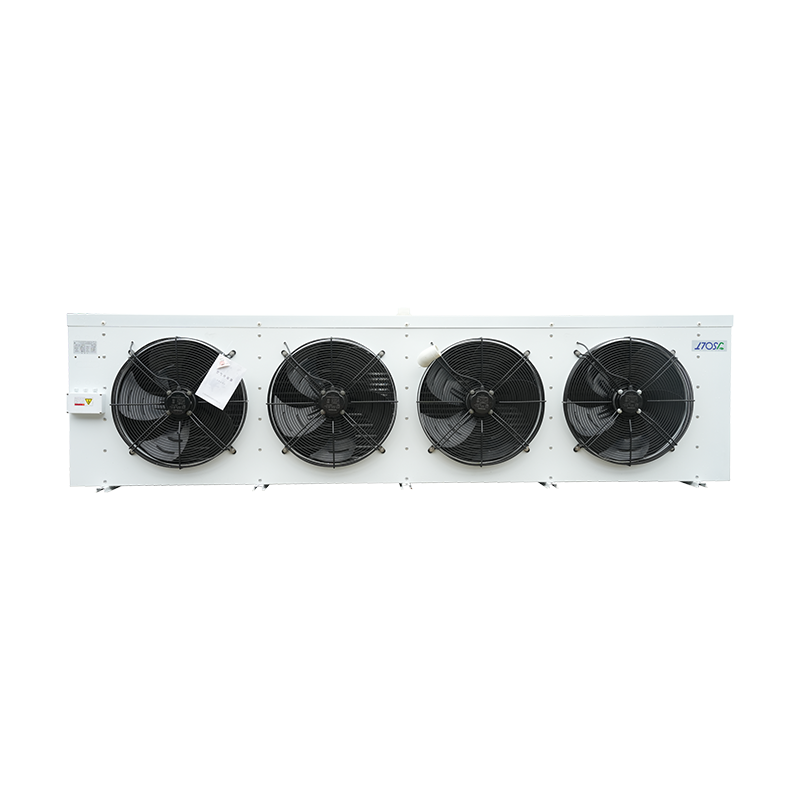

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español