Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

What's the difference between an ICEMachine and a home ice maker?

The Difference Between an ICE Machine and a Home Ice Maker

1. Design Capacity and Power Range

The ICE Machine is designed for industrial mass production, with a single unit power range from ¼HP to 100HP, meeting the ice-making needs of large-scale commercial, catering, and cold chain facilities. Home ice makers, on the other hand, typically have a power of less than 0.1HP and are only suitable for small, daily applications.

This power difference determines the order of magnitude difference in ice-making speed and daily ice production. The ICE Machine can produce hundreds of kilograms of ice cubes in a few hours, while the ICE Machine can only produce tens of cubes.

2. Refrigeration System and Energy Efficiency

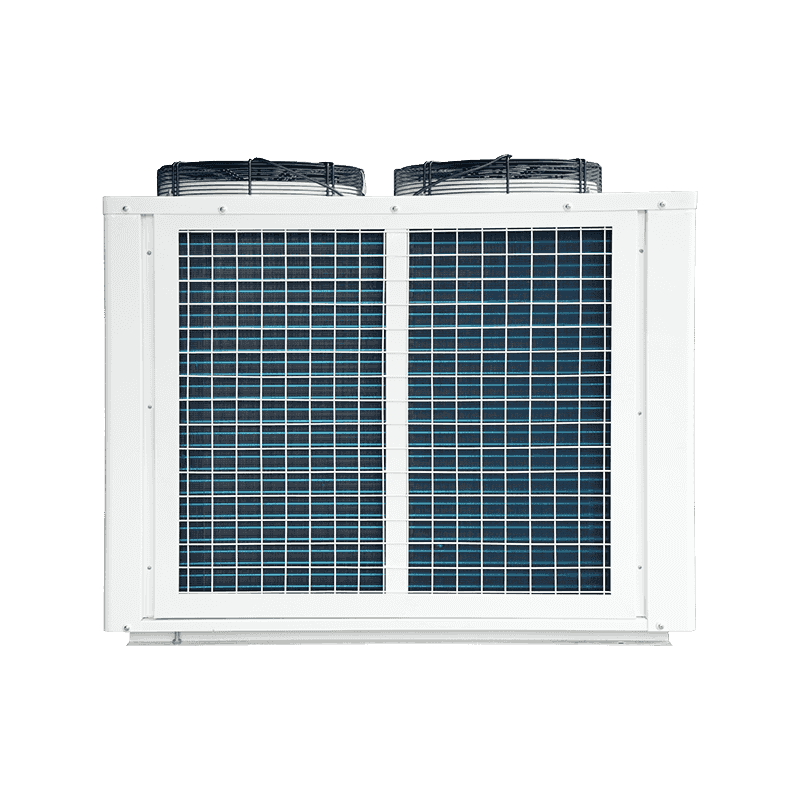

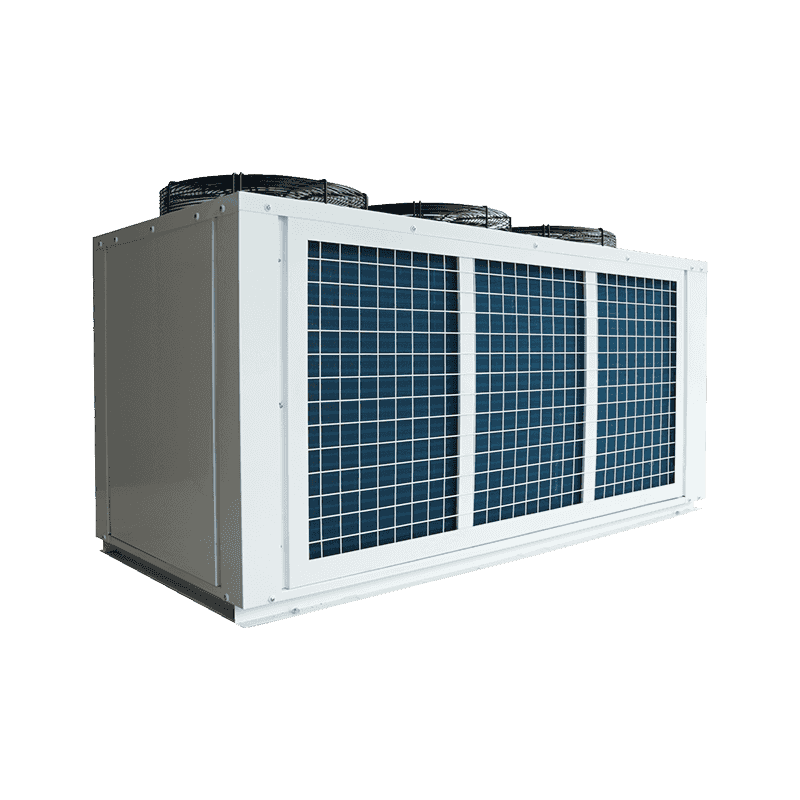

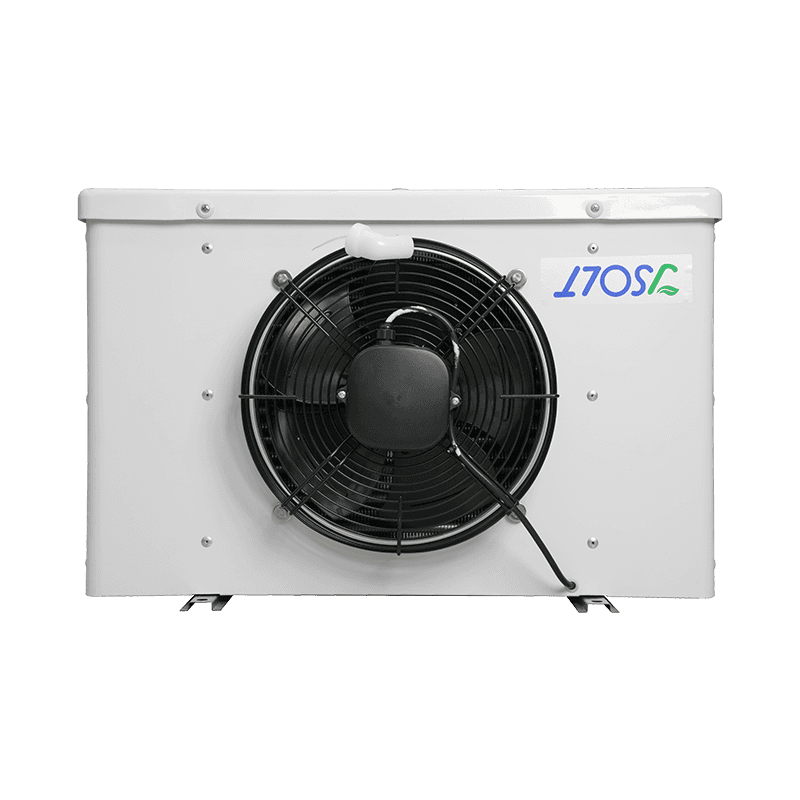

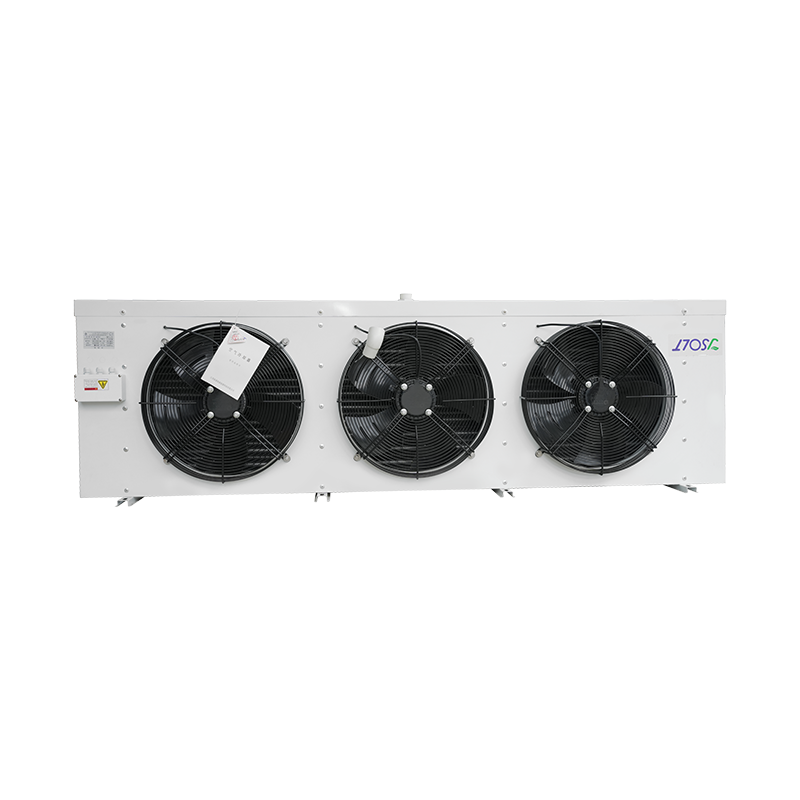

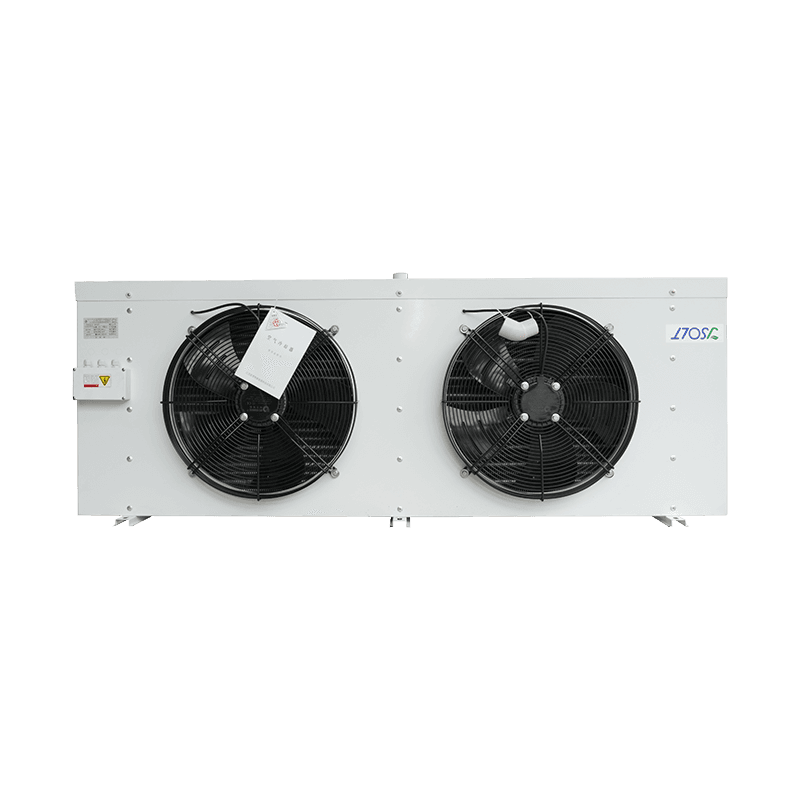

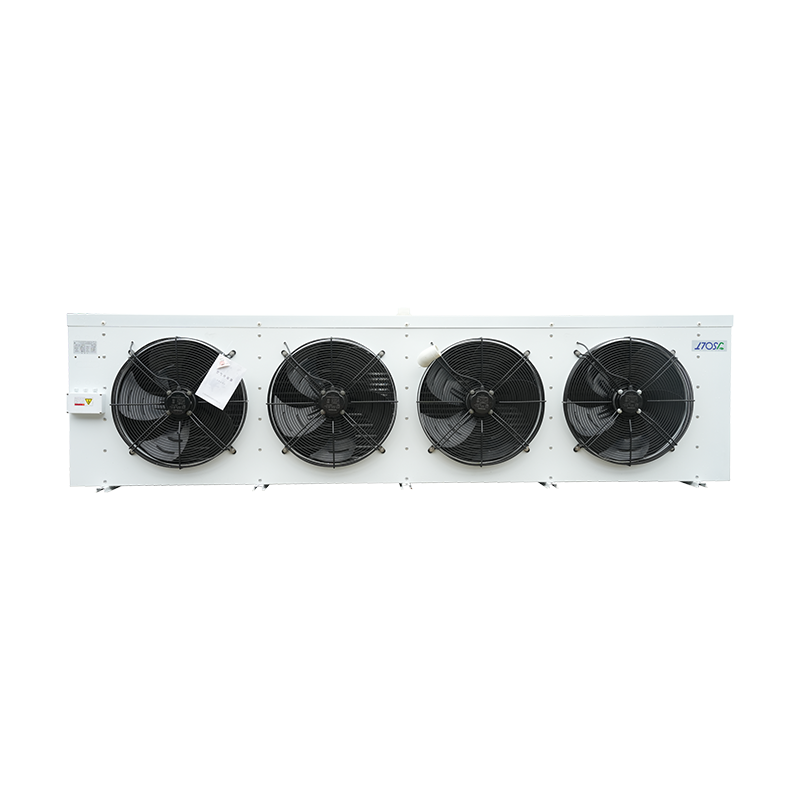

The ICE Machine utilizes high-efficiency compressors, air- or water-cooled condensers, and is equipped with a dedicated R&D and testing center. The product has obtained international certifications such as CE and ISO9001, ensuring stable performance in various operating environments.

Home ice makers often use small compressors and simple heat sinks, resulting in relatively low energy efficiency and a lack of systematic quality testing. 3. Structural Layout and Maintenance Ease

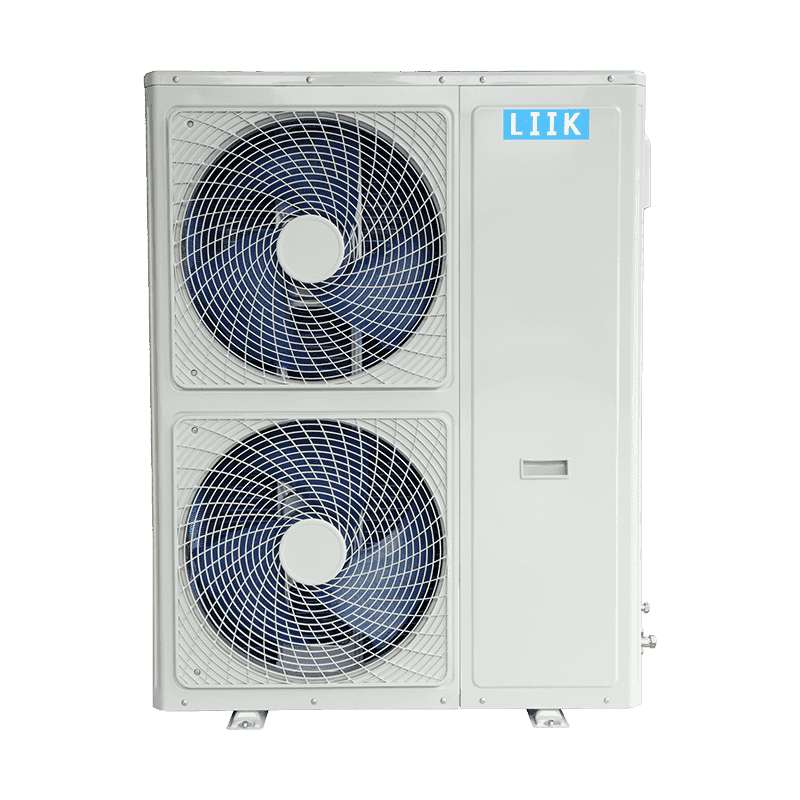

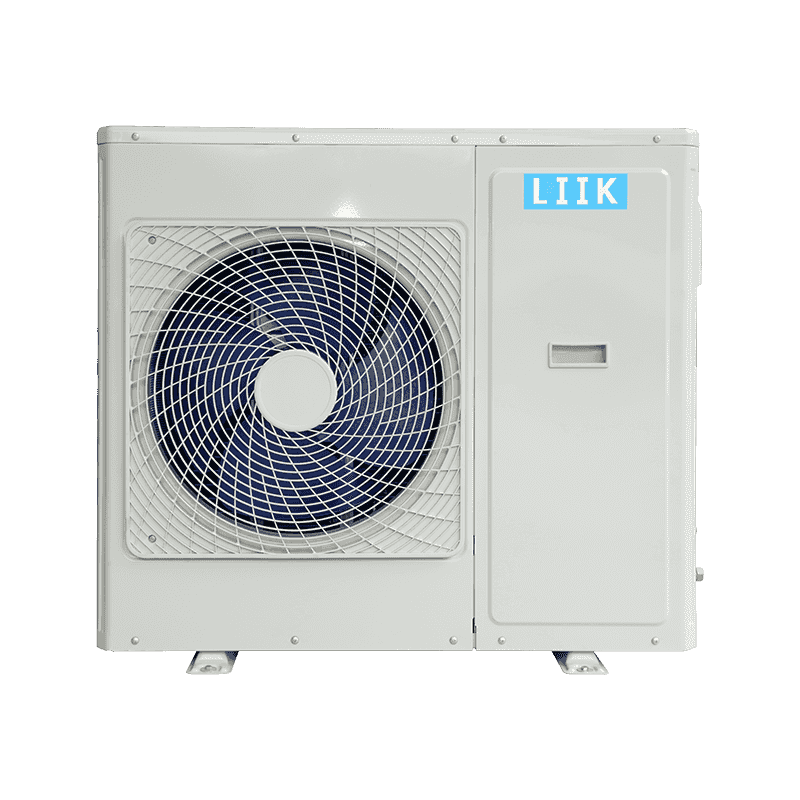

Industrial units utilize a modular design with a metal casing. The three main functional areas within the unit—refrigeration, ice making, and ice storage—are clearly defined, facilitating on-site maintenance and component replacement. The upright ice machine shown in the image exemplifies this structure, with its upper and lower layers, independent air-cooled condensers, and visual control box.

Home ice machines are small and compact, with highly integrated internal components. Repairs often require complete replacement, resulting in higher maintenance costs.

4. Application Scenarios and Certification Requirements

ICE Machine primarily serves high-load applications such as commercial kitchens, supermarket freezers, hotels and bars, and industrial cold chains. Our products have obtained EU mandatory certifications such as CE and ROHS, and we have a global export network, with annual export volume exceeding hundreds of millions of yuan and sales to over 100 countries and regions.

Home ice machines are limited to home kitchens or small offices and typically only need to meet domestic safety standards, not requiring additional international certification.

How can common ice machine faults be quickly diagnosed and corrected?

Quick Diagnosis and Troubleshooting of Common Ice Maker Faults

1. Refrigerant Leak or Compressor Failure

Observe the unit for unusual noises, difficulty starting, or a significant decrease in ice production. Use a pressure gauge to check whether the high and low pressure sides are within the rated range. If the pressure is abnormal and accompanied by oil stains, it may indicate a refrigerant leak.

Solution: Replace or repair the compressor, recharge with refrigerant that meets specifications, and perform a system vacuum test.

2. Ice Blockage and Drain System Problems

Ice accumulation in the ice outlet or ice storage bin can cause poor ice dispensing or water leakage. Check the drain pipe for blockage by ice or dirt, and clean the drain valve and piping.

Solution: Perform regular de-icing operations, flush the drain pipe with warm water, and replace any deteriorated drain valves if necessary.

3. Control System Failure

The electronic control box displays an error code or the panel is unresponsive. First, check whether the power supply is stable, then use a multimeter to measure the voltage output of the control board. Solution: Reset the control system (power off for 5 minutes, then power back on). If the error code persists, replace the faulty sensor or main control board.

4. Performance degradation due to insufficient maintenance

Prolonged failure to clean the condenser fins can lead to poor heat dissipation, increased compressor load, and reduced ice-making efficiency.

Solution: Regularly (recommended every 3 months) clean dust and debris from the condenser surface, check that the fan is operating properly, and maintain good ventilation around the unit.

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español