Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

What are the main components of Ice Making Condensing Units?

Ice Making Condensing Units are essential devices in commercial and industrial ice production. They play a critical role in efficiently converting water into ice while maintaining energy efficiency and system reliability. Understanding their main components helps operators optimize performance and reduce maintenance costs. These units are widely used in industries such as food processing, hospitality, fisheries, and supermarkets.

1. Compressor

The compressor is the heart of an Ice Making Condensing Unit. It compresses the refrigerant gas, raising its pressure and temperature before sending it to the condenser. Compressors can be of several types:

- Reciprocating compressors: Suitable for small to medium ice machines. They provide reliable performance but can be noisier.

- Scroll compressors: Highly efficient and quieter, ideal for modern commercial units.

- Screw compressors: Typically used in large industrial ice-making applications due to their high capacity and durability.

Choosing the right compressor affects the ice production rate, energy consumption, and overall system lifespan.

2. Condenser

The condenser is responsible for releasing the heat absorbed from the evaporator and refrigerant. There are two primary types:

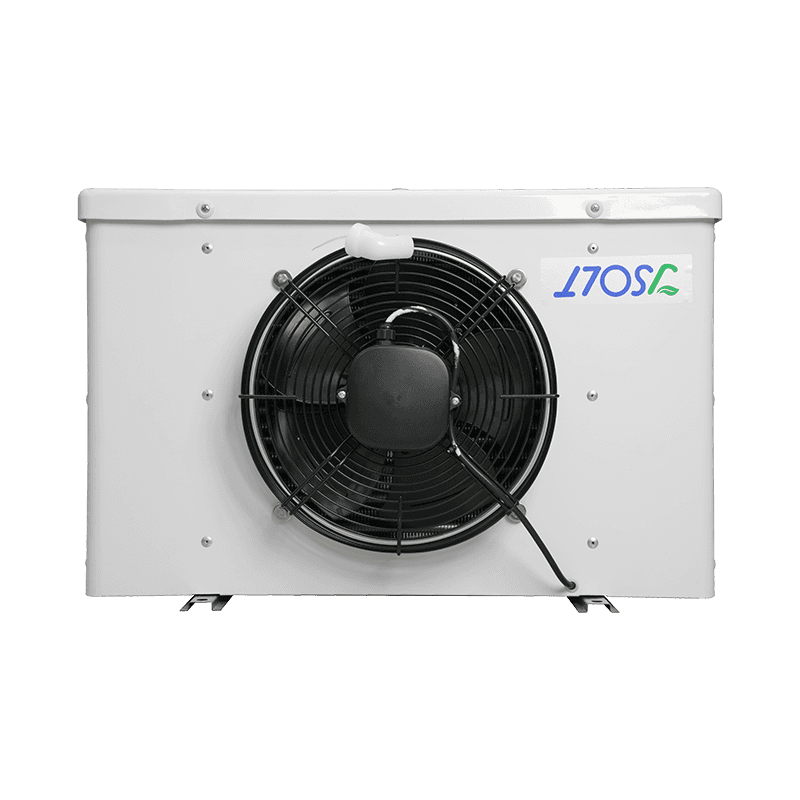

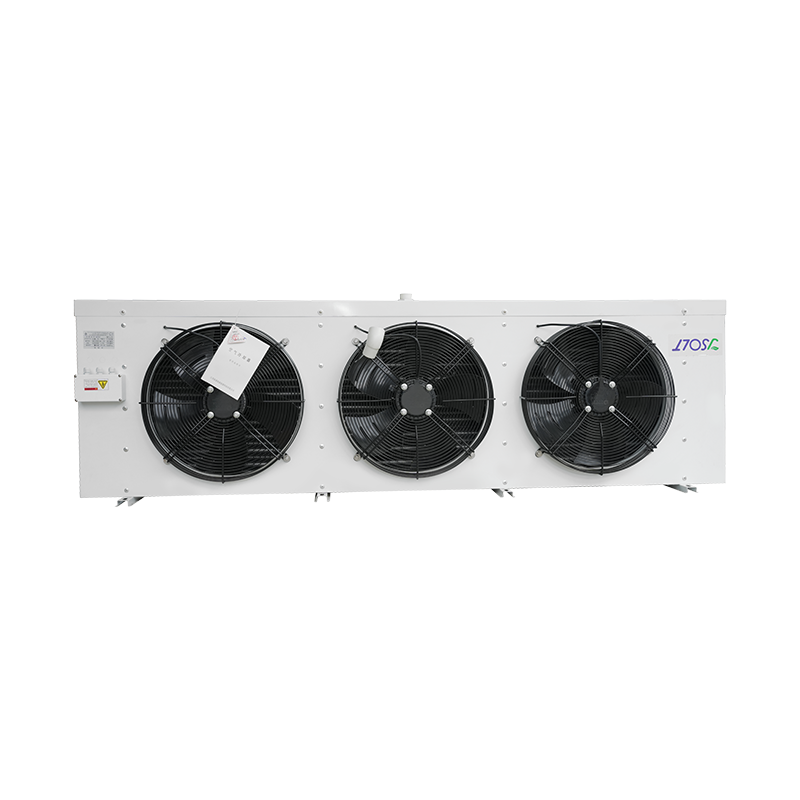

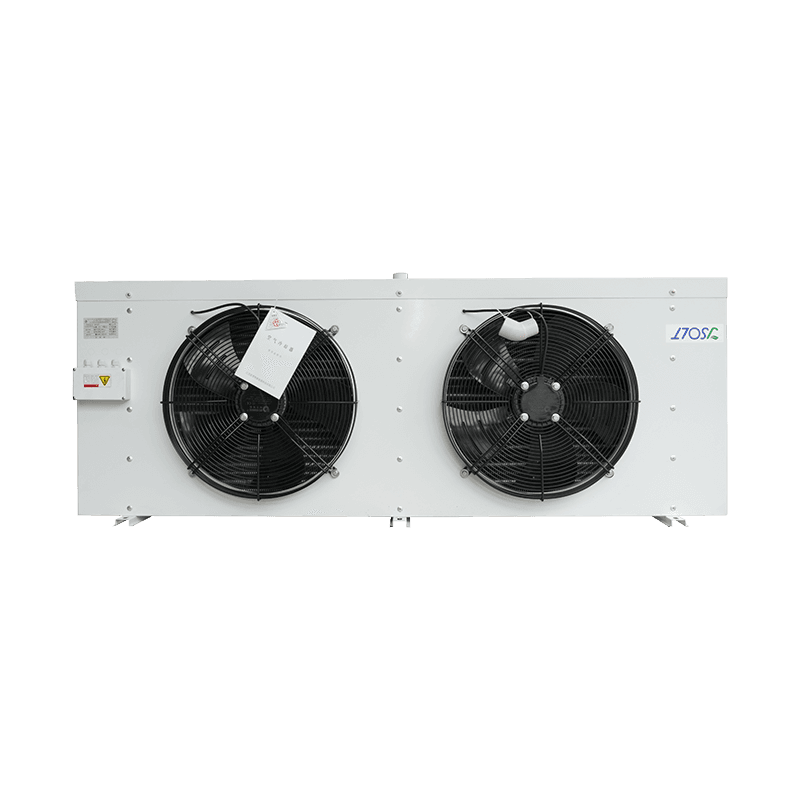

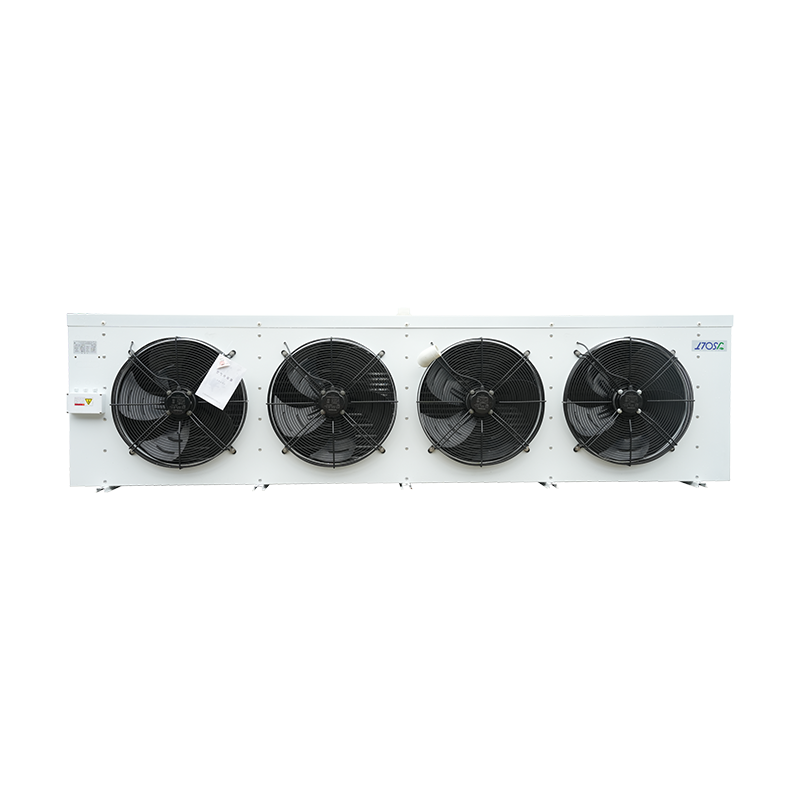

- Air-cooled condensers: Common in small and medium units. They rely on fans to blow air over the coils. They are easier to maintain but may be less efficient in hot environments.

- Water-cooled condensers: Used in high-capacity or industrial applications. They require a water source but provide better efficiency and lower energy costs.

Efficiency of the condenser directly impacts ice-making speed and energy usage.

3. Evaporator

The evaporator is where the ice actually forms. Refrigerant absorbs heat from water passing over or through the evaporator, causing the water to freeze. Types of evaporators include:

- Shell-and-tube evaporators: Common for flake ice machines, providing fast freezing and easy maintenance.

- Plate evaporators: Used for block ice production, where water freezes on flat plates.

- Spiral evaporators: Often used in large industrial units, capable of producing high volumes of ice continuously.

The design of the evaporator affects ice shape, freezing speed, and energy efficiency.

4. Expansion Valve

The expansion valve regulates the flow of refrigerant into the evaporator, maintaining the correct pressure and temperature for ice formation. Common types include:

- Thermostatic expansion valves (TXV): Automatically adjust refrigerant flow based on evaporator temperature.

- Capillary tubes: Simple and cost-effective, mostly used in smaller units.

Proper valve selection ensures uniform ice production and prevents refrigerant waste.

5. Refrigerant

The choice of refrigerant is crucial for efficiency and environmental compliance. Modern ice-making units use refrigerants such as R404A, R134a, or natural refrigerants like ammonia (R717) in industrial applications. Refrigerants transfer heat efficiently and influence energy consumption, operating costs, and environmental impact.

6. Fans and Pumps

Fans and pumps ensure proper circulation of air and water. Air-cooled condensers use fans to remove heat, while water-cooled systems rely on pumps to circulate water over condenser coils. Efficient fans and pumps reduce energy costs and maintain stable ice production.

7. Control System

The control system automates operation, monitors performance, and protects the unit from damage. Features may include:

- Temperature and pressure sensors

- Automatic start/stop and defrost cycles

- Remote monitoring capabilities

An advanced control system increases reliability and allows operators to optimize ice production based on demand.

8. Protective Components

Ice Making Condensing Units include protective devices to prevent damage and maintain safety:

- High/low-pressure switches: Prevent system overpressure or vacuum conditions.

- Overload relays: Protect the compressor from electrical faults.

- Water level sensors: Ensure consistent ice quality by controlling water flow.

Comparison of Key Components

| Component | Small Units | Large Industrial Units |

|---|---|---|

| Compressor | Reciprocating, Scroll | Screw, Scroll |

| Condenser | Air-cooled | Water-cooled |

| Evaporator | Plate, Shell-and-tube | Spiral, Large Plate |

| Expansion Valve | Capillary Tube | Thermostatic Expansion Valve |

FAQs About Ice Making Condensing Units

Q1: How often should Ice Making Condensing Units be maintained?

Routine maintenance should be performed every 3-6 months, including cleaning the condenser, checking refrigerant levels, inspecting fans, and ensuring water quality. Regular maintenance extends the lifespan of the unit and ensures consistent ice production.

Q2: Can I use the same unit for different types of ice?

Yes, but the evaporator type and control system must support the desired ice shape, whether it’s flake, block, cube, or nugget ice. High-capacity industrial units may include modular evaporators for versatility.

Q3: Which type of condenser is more efficient?

Water-cooled condensers are generally more efficient and cost-effective for large-scale operations, especially in hot climates. Air-cooled condensers are simpler, easier to install, and suitable for small or medium units.

Q4: What are the common issues in Ice Making Condensing Units?

- Refrigerant leaks reducing cooling efficiency

- Fouling or scaling on evaporator or condenser surfaces

- Faulty fans or pumps affecting ice production

- Electrical problems with compressors or control systems

Q5: How to improve energy efficiency?

Optimizing refrigerant choice, using variable-speed compressors, regular cleaning of condensers, and using advanced control systems all improve energy efficiency and reduce operating costs.

Conclusion

Understanding the main components of Ice Making Condensing Units—including compressors, condensers, evaporators, expansion valves, refrigerants, fans, pumps, and control systems—is essential for maintaining high performance and efficiency. Proper selection, maintenance, and operation ensure reliable ice production while minimizing energy consumption and operating costs. By comparing different component types and following best practices, businesses can optimize their ice-making operations for commercial or industrial use.

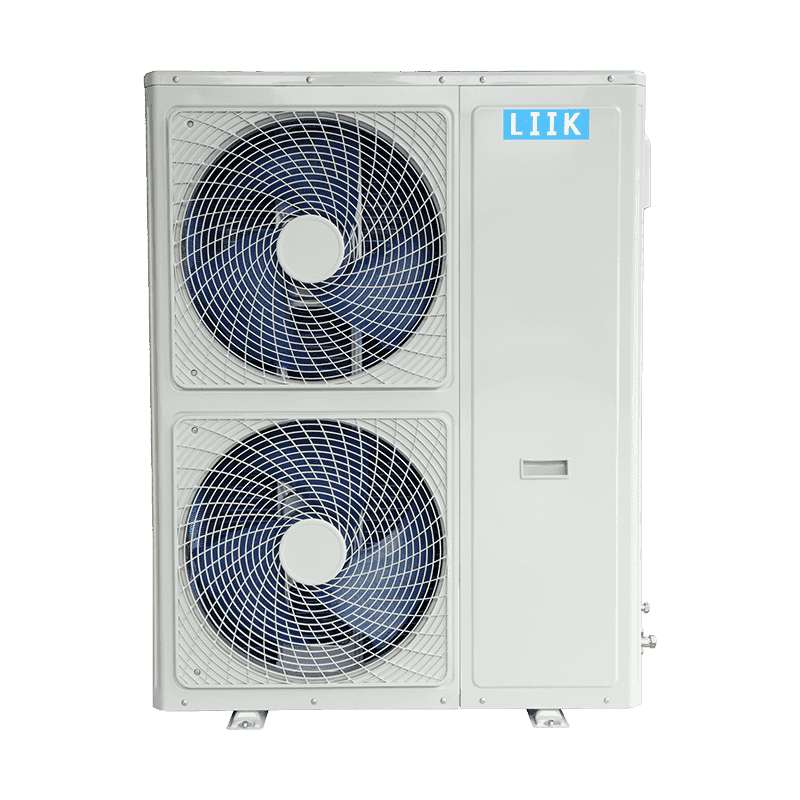

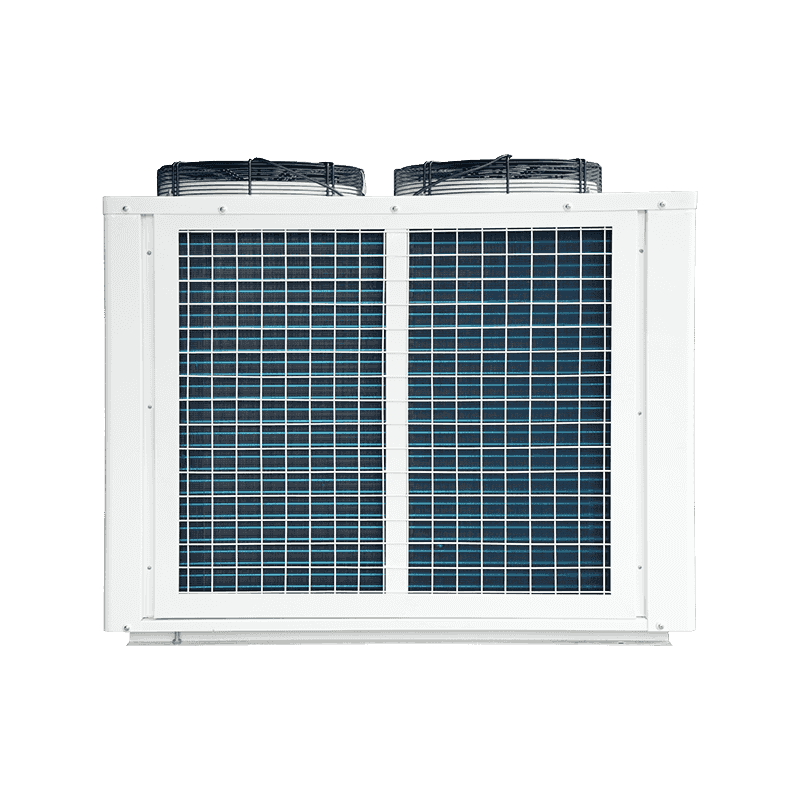

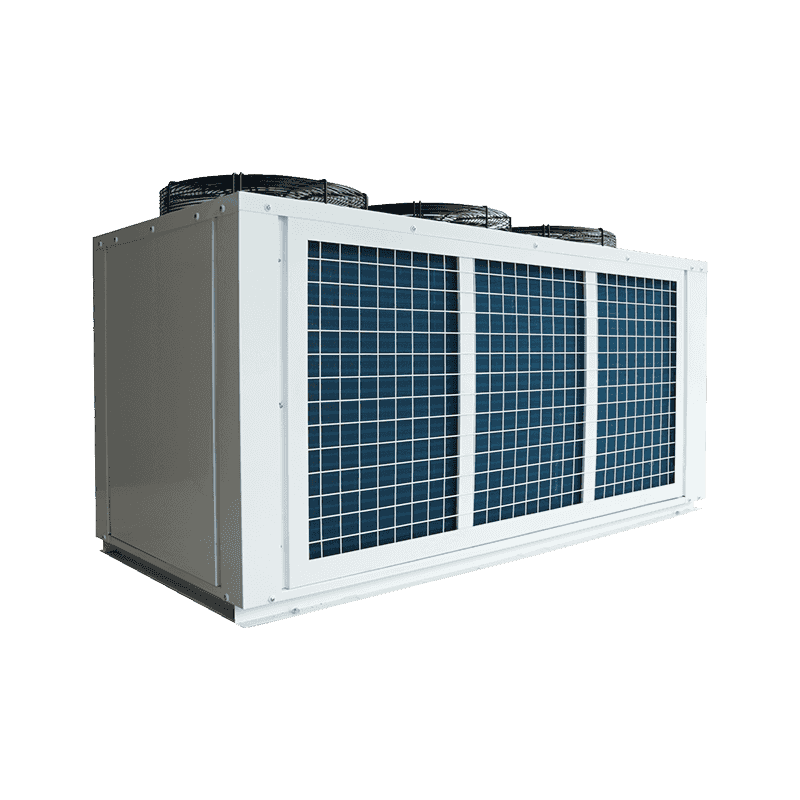

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español