Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

Why does the evaporator always scale up?

Evaporator scaling is a common problem in industrial refrigeration and automotive air conditioning systems. Scaling not only affects heat transfer efficiency but also shortens equipment lifespan. The following are the main reasons and preventive measures:

1. Water Hardness and Salt Deposition

The water quality in the evaporator is the root cause of scaling. Dissolved salts (such as sodium chloride, calcium sulfate) and metal ions (such as calcium, magnesium) in the water will gradually precipitate in the high-temperature evaporation environment, attaching to the heat exchange surface and forming a hard scale layer.

Root cause: Minerals in hard water deposit as the water evaporates and concentrates.

Impact: The formed calcium and magnesium carbonate scale (hard scale) will severely hinder heat conduction.

Prevention: It is recommended to use softened water or deionized water as the cooling medium.

2. Operating Temperature and Chemical Precipitation

Temperature is a key factor affecting the scaling rate. As the evaporator temperature increases, the solubility of dissolved salts in the water decreases, making it easier for crystals to precipitate.

Temperature effect: Increased temperature reduces salt solubility, leading to salt crystallization and precipitation.

Scaling type: Hard scaling (such as calcium carbonate) is most common in high-temperature environments.

Optimization: Reasonably control the evaporation temperature and avoid unnecessary overheating.

3. Equipment Design and Flow Problems

Improper internal structure and fluid distribution design of the evaporator can lead to the accumulation of scaling substances in local areas.

Design flaws: Uneven water flow distribution or unreasonable dead-end designs can lead to localized accumulation of scale.

Material flow: Uneven material distribution can easily lead to overheating and scorching of the scale layer, affecting heat transfer efficiency.

Improvement: Optimize the heat exchange tube design and fluid distributor to ensure uniform fluid flow.

4. Lack of Timely Maintenance and Cleaning

Lack of regular maintenance and cleaning will lead to the gradual thickening of the scale layer, ultimately affecting equipment performance.

Lack of maintenance: Long-term lack of cleaning will lead to the gradual thickening of the scale layer, affecting heat transfer efficiency.

Cleaning methods: Traditional chemical cleaning is effective, but appropriate cleaning agents must be selected to prevent equipment corrosion.

Recommendation: Regularly perform online cleaning or shutdown cleaning to maintain the efficient operation of the evaporator.

←

How to determine if the condensing unit capacity selection is appropriate?

→

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

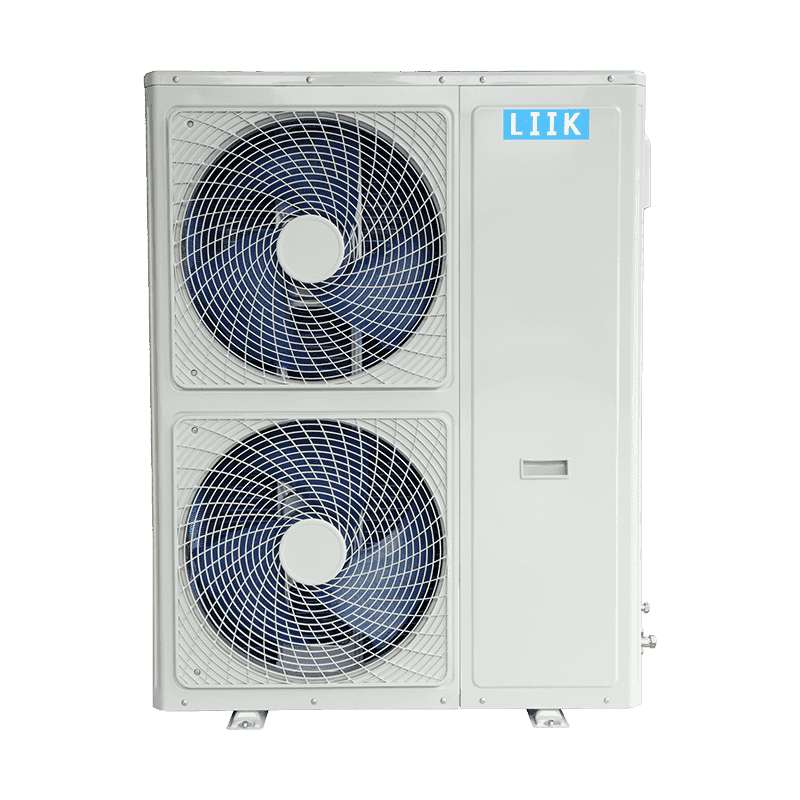

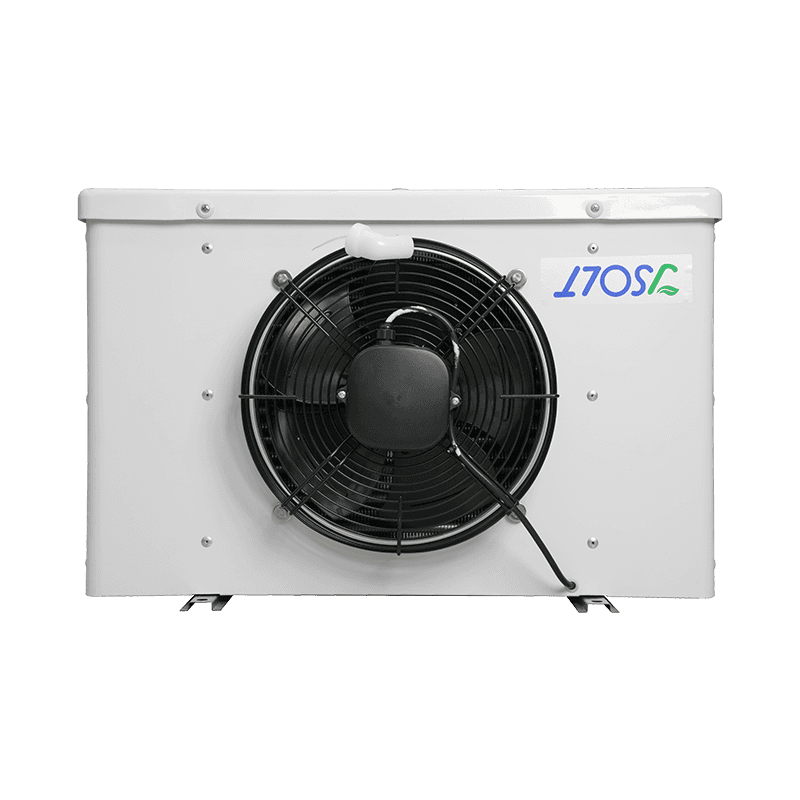

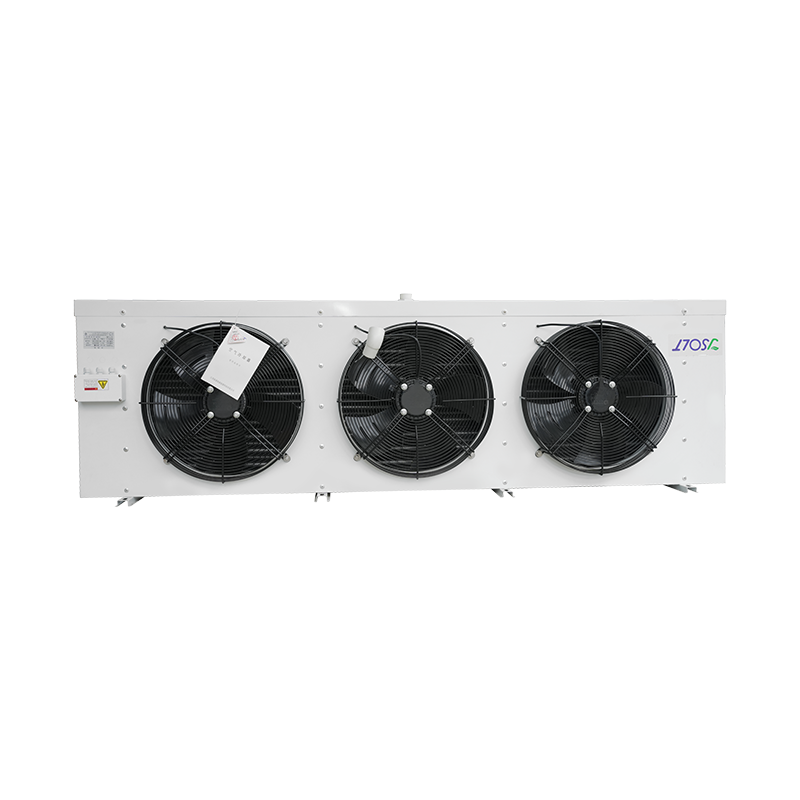

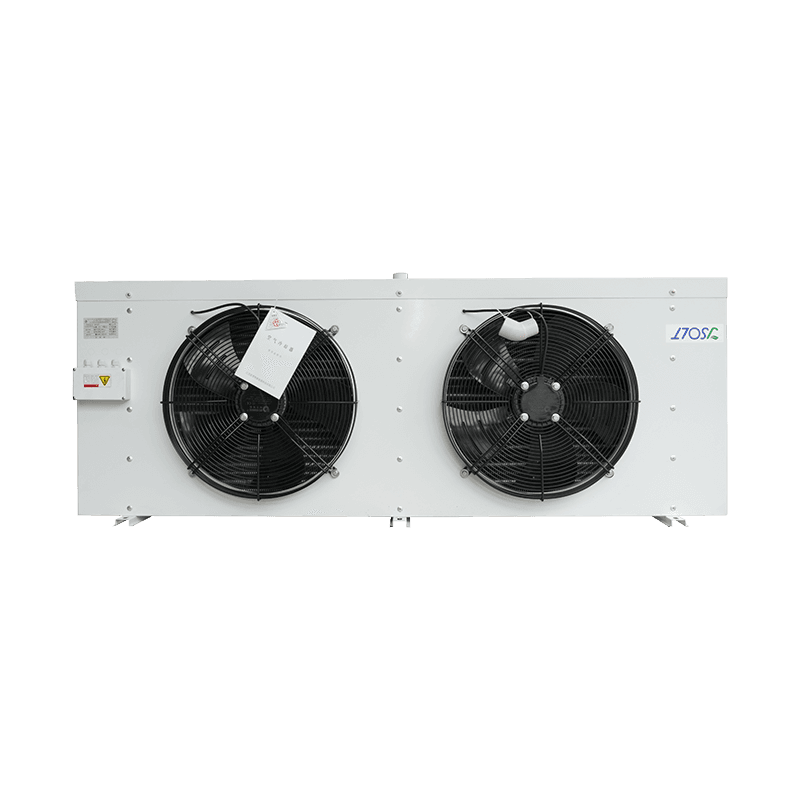

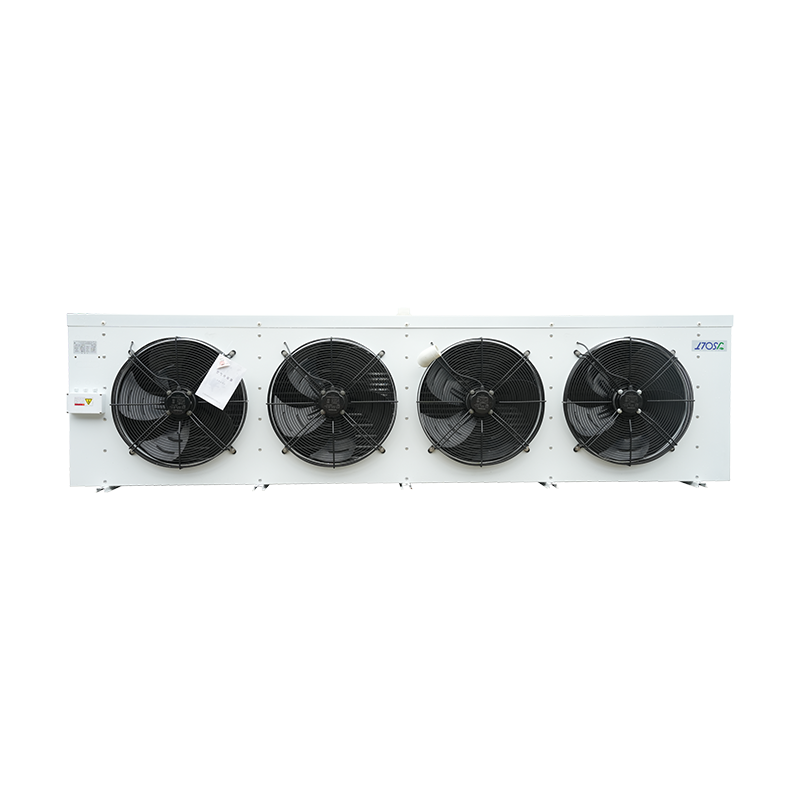

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español