Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

What are the specific steps in the vapor compression refrigeration cycle used in household refrigerators?

Specific Steps of the Vapor Compression Refrigeration Cycle Used in Household Refrigerators

1. Compressor Intake and Isentropic Compression

Low-pressure, low-temperature refrigerant vapor is drawn into the compressor and isentropically compressed, increasing its pressure and transforming it into high-temperature, high-pressure, superheated steam.

2. Condenser

Heat Dissipation

The high-temperature, high-pressure steam enters the condenser, where it dissipates heat and cools under constant pressure, condensing into a high-pressure, subcooled liquid.

3. Dehumidification Filter

The liquid refrigerant passes through the filter drier, removing moisture and impurities to prevent ice and dirt blockage and ensure smooth subsequent throttling.

4. Expansion Valve (or Capillary Tube)

The subcooled liquid passes through the expansion valve, adiabatically throttling it, causing a sudden drop in pressure and temperature, forming a low-pressure, low-temperature mixed phase.

5. Evaporator

The low-pressure refrigerant absorbs heat from the refrigerator's interior in the evaporator, vaporizing into low-pressure steam, achieving the cooling effect.

6. Circulation Returns to the Compressor

The evaporated low-pressure steam is drawn back into the compressor, completing the cycle.

How to determine if a refrigeration system is leaking or lacking refrigerant?

1. Visual inspection for oil stains and bubbles

Inspect the system casing and piping for oil stains or bubbles caused by soapy water. Oil stains are often a visible sign of a refrigerant leak.

2. Electronic leak detector testing

Use an electronic halogen leak detector to detect the halogen content in the refrigerant. An alarm or a change in the instrument value indicates a leak.

3. Nitrogen pressure leak testing

Pour nitrogen gas (approximately 0.8 MPa) into the system and observe whether the pressure drops over a period of time. A drop in pressure indicates a leak in the system.

4. Vacuum leak testing

Evacuate the system and hold it for several hours. If the vacuum level returns, it indicates a small leak.

5. Pressure differential monitoring

Compare the pressure difference between the high-pressure and low-pressure sides. An abnormal increase often indicates a leak in the piping or valve or a lack of refrigerant.

Content

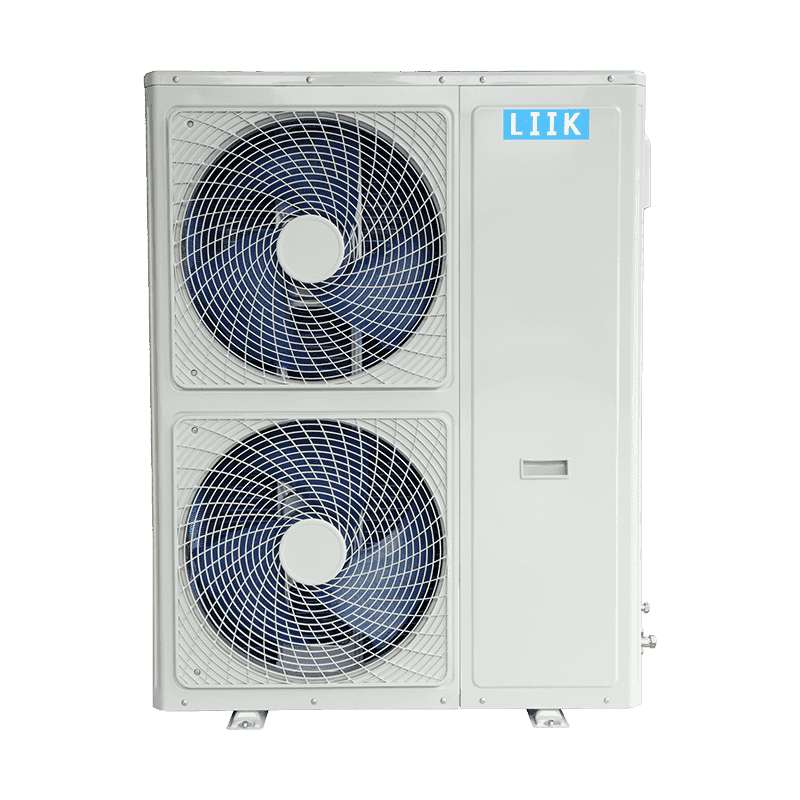

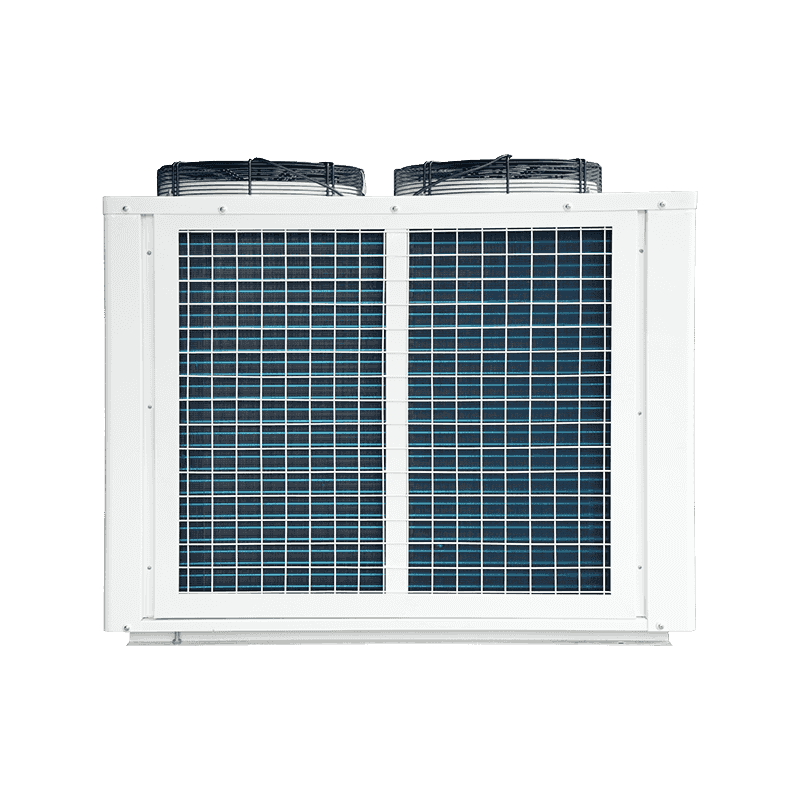

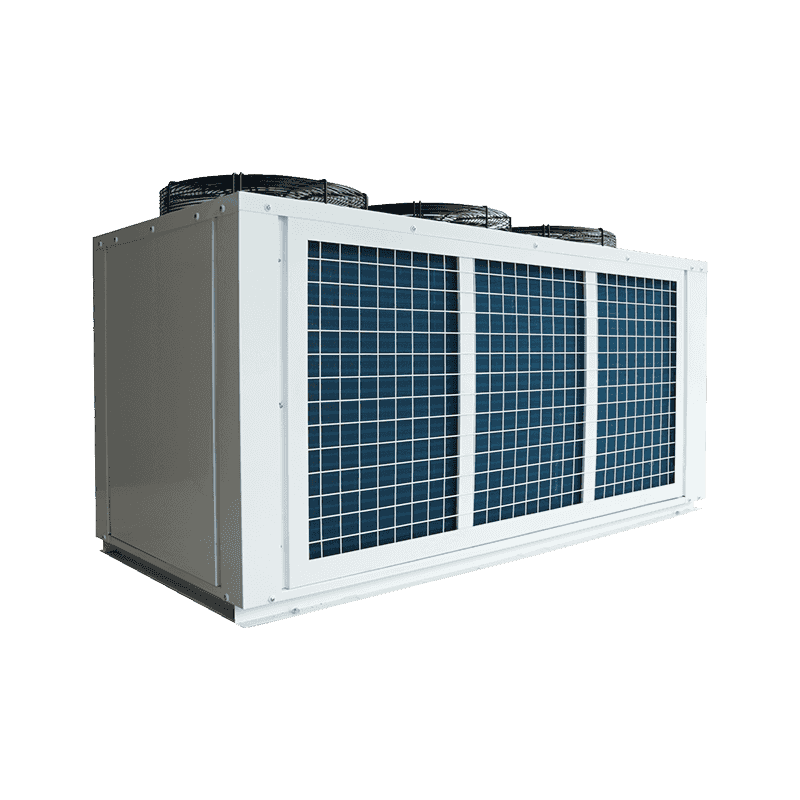

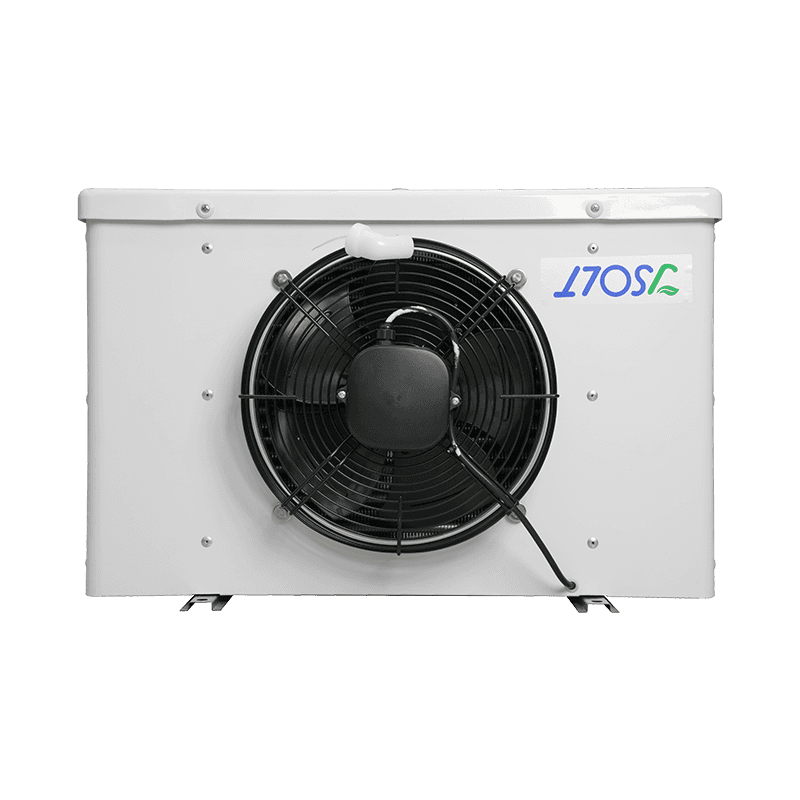

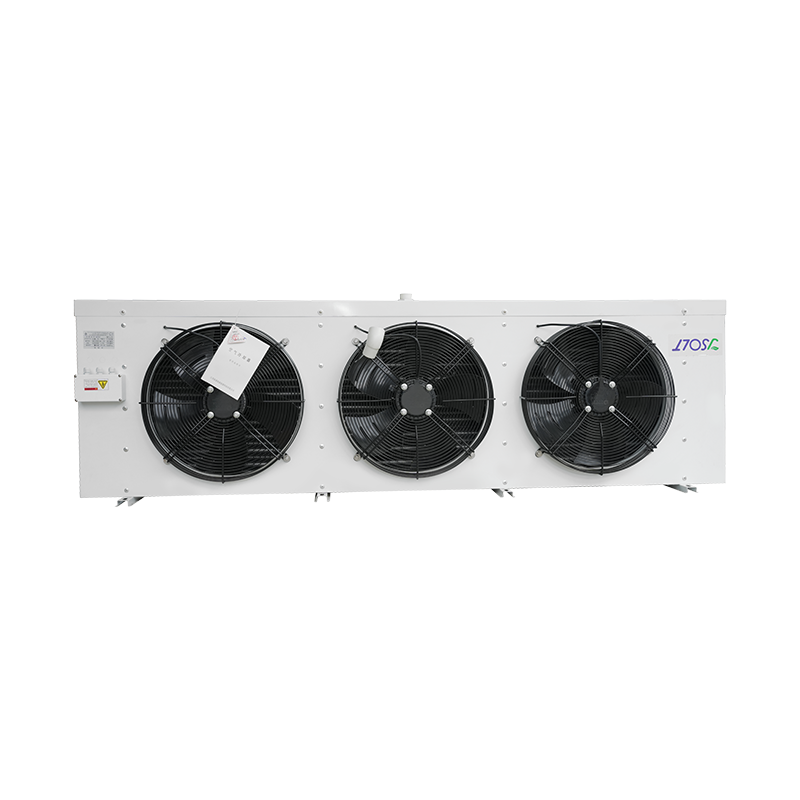

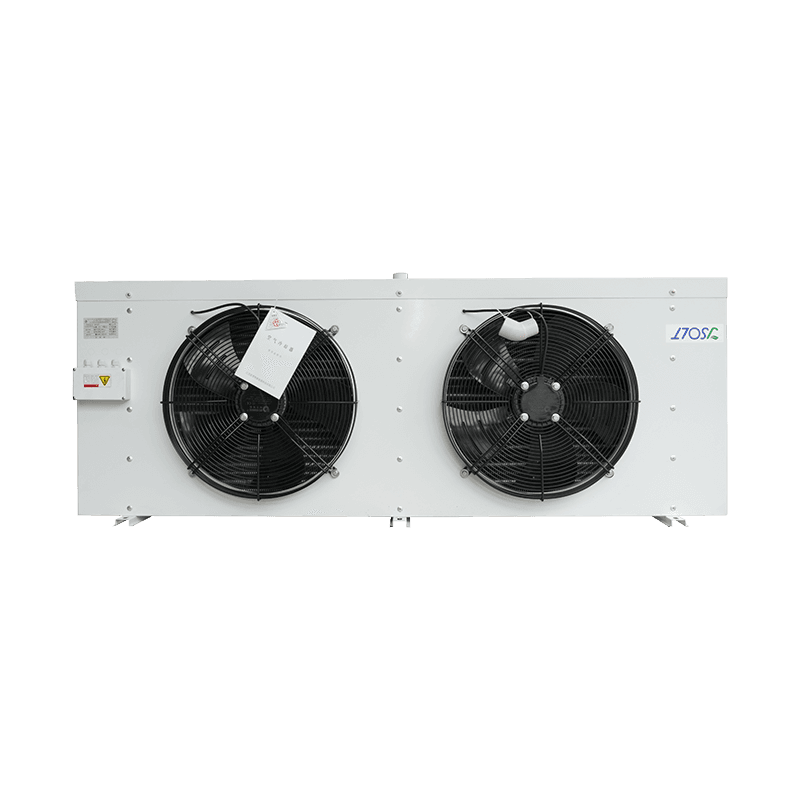

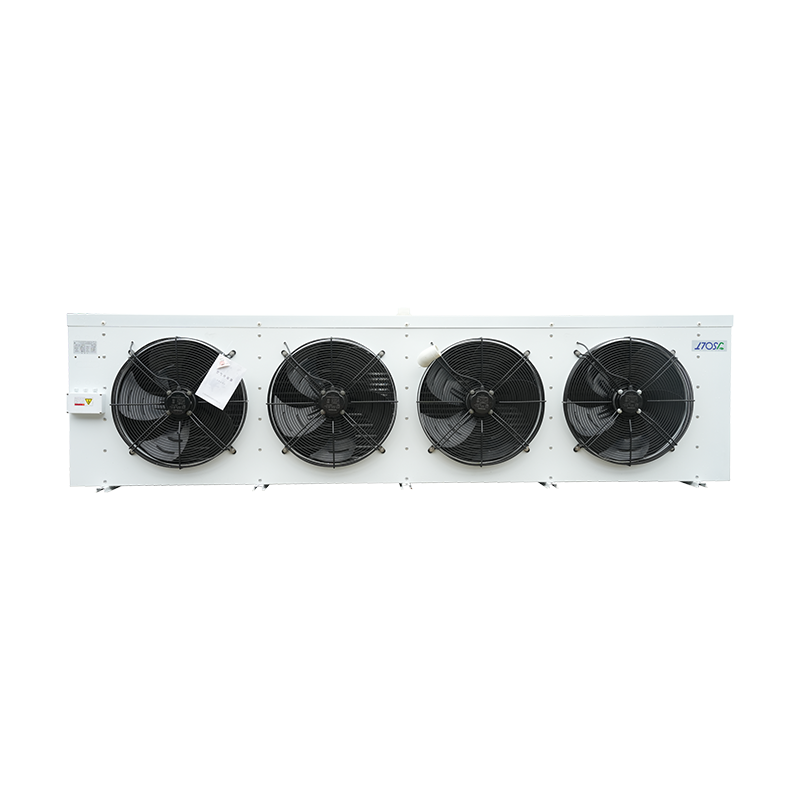

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español