Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

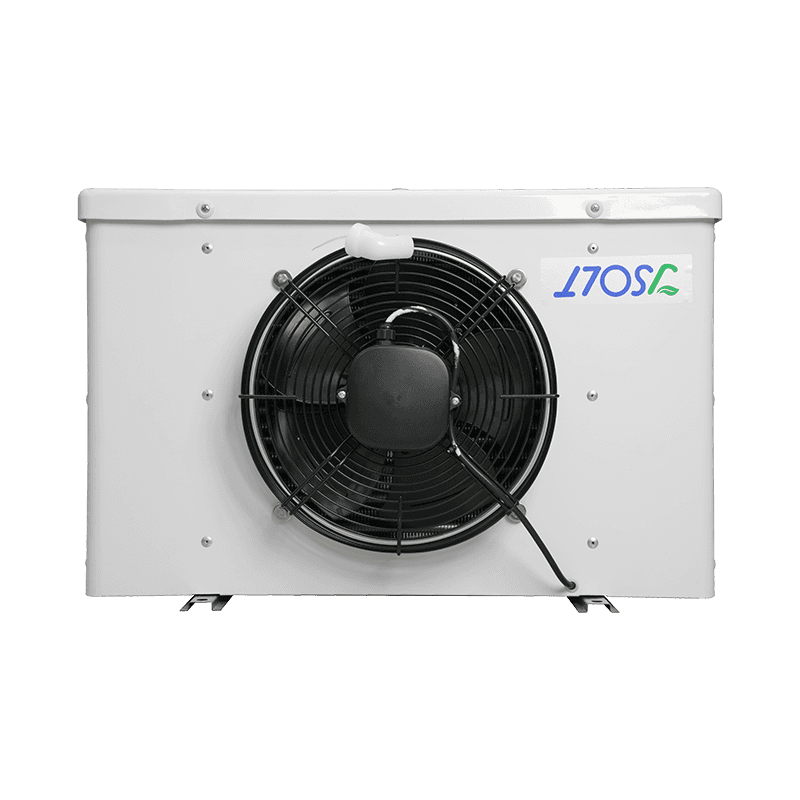

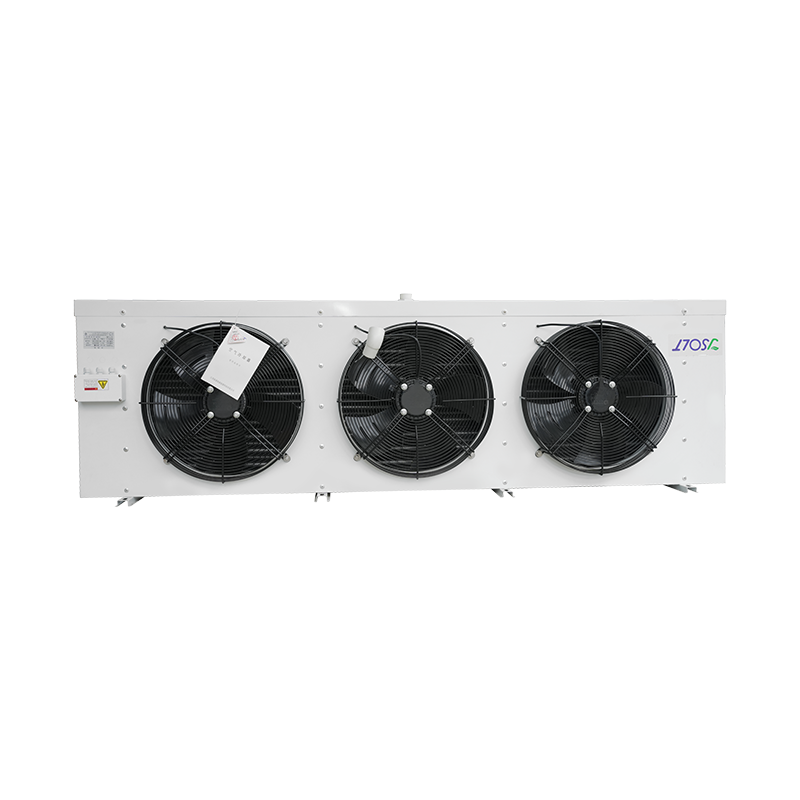

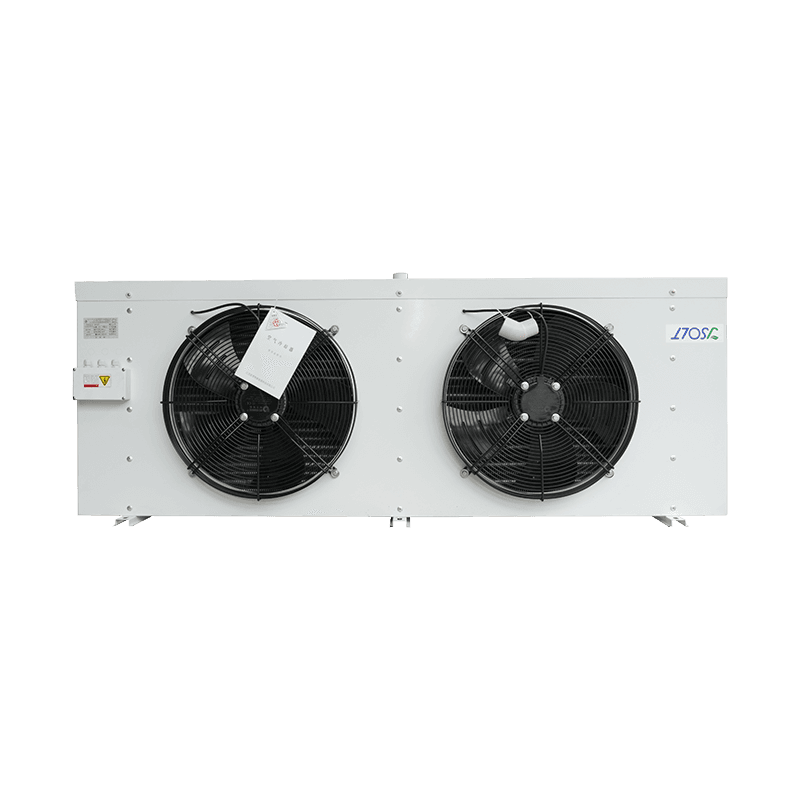

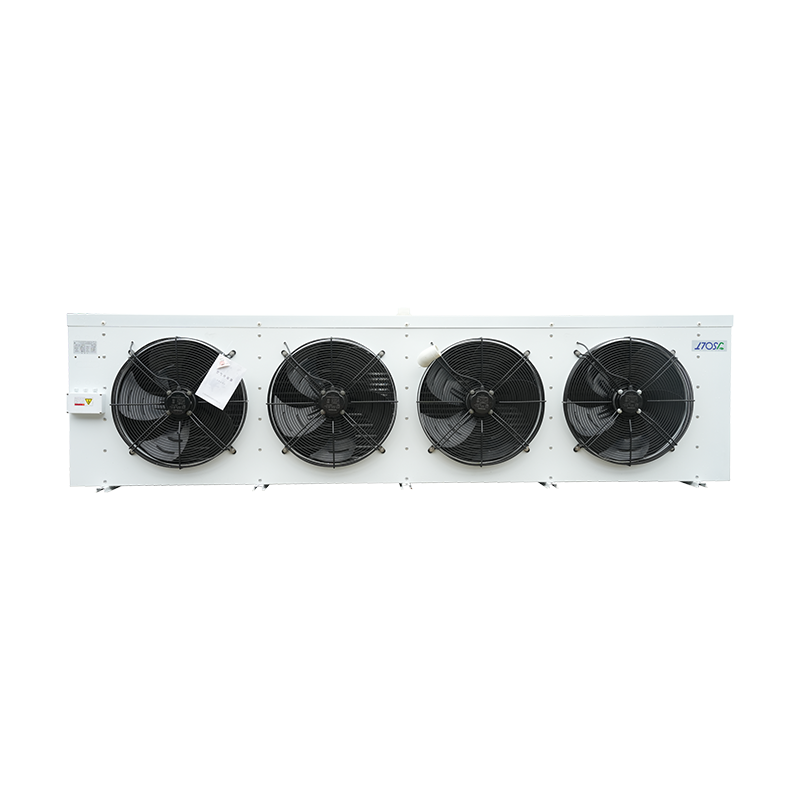

What is an air cooler?

Air Cooler Overview

1. Working Principle

An air cooler uses a built-in high-speed fan to force fresh outside air into the core component of a heat exchanger containing a cooling medium (commonly clean tap water or a special evaporator). The cooling medium evaporates rapidly on the porous or corrugated surface of the heat exchanger, absorbing a large amount of heat energy during the evaporation process, significantly lowering the temperature of the air passing through. The cooled air is then accelerated again by the fan and evenly returned to the room, achieving further cooling. The entire cycle does not involve a compressor or high-pressure refrigerant cycle, resulting in relatively low energy consumption and a simpler structure.

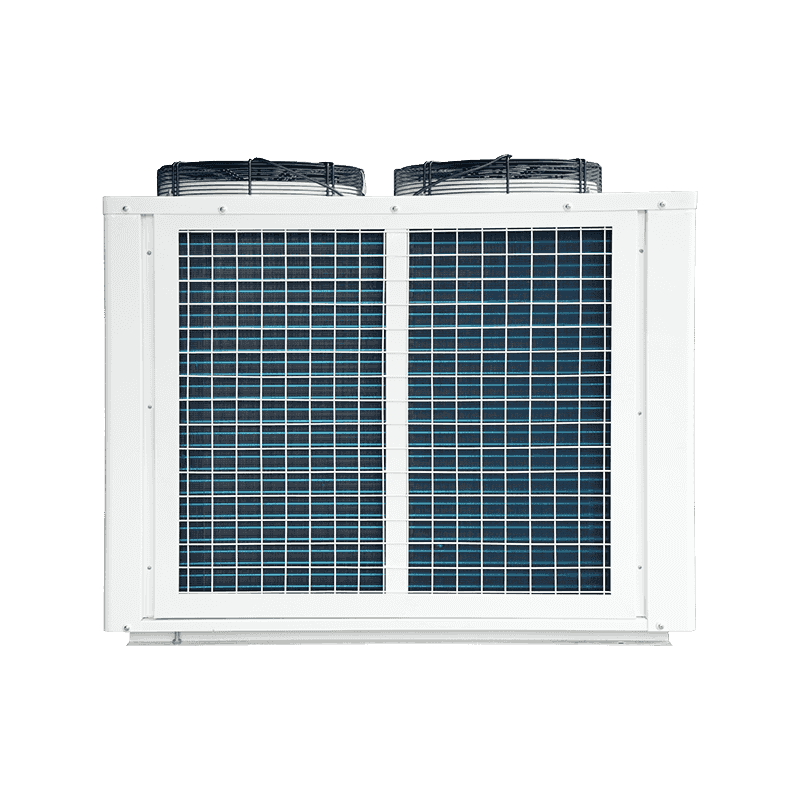

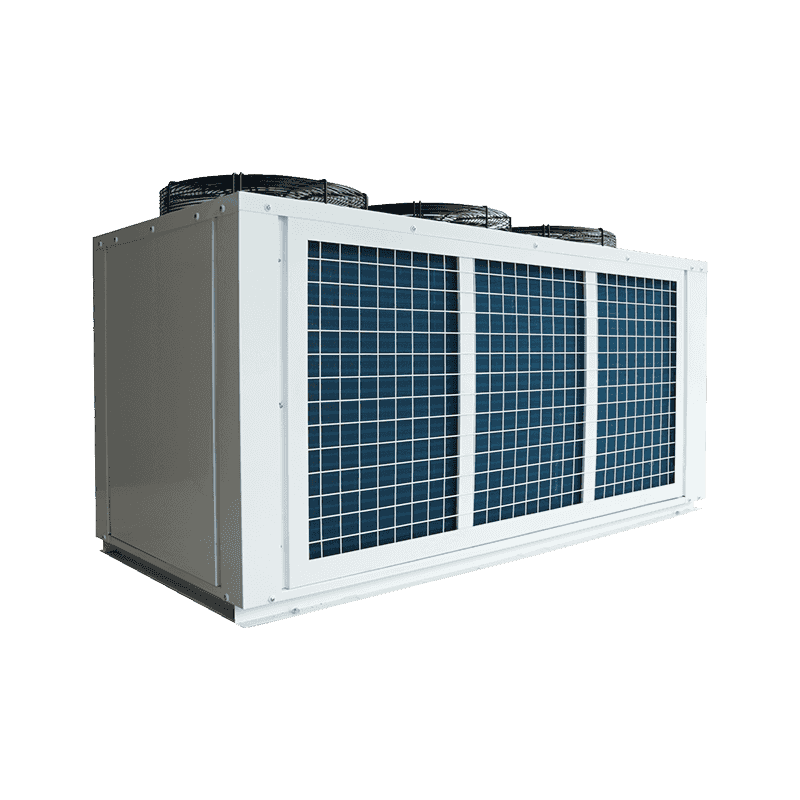

2. Core Components

Metal Casing: Provides robust protection against external impacts to internal components, while also offering corrosion resistance and heat dissipation.

Heat Exchanger Block: Typically made of high thermal conductivity aluminum alloy or stainless steel, with a surface designed with fine corrugations or perforations to increase the contact area with the cooling medium and improve evaporation efficiency.

Drive Motor and Fan: The motor provides power to drive the fan, generating a strong airflow. The fan blades are optimized for shape and speed to reduce noise while maintaining airflow.

The inlet and outlet media collection system, including inlet and outlet pipes and a water pump (if a circulating water system is used), is responsible for evenly distributing the cooling medium across the heat exchanger surface and promptly draining evaporated water.

The condensate drainage system collects and removes condensate generated during evaporation, preventing backflow or accumulation inside the unit and ensuring long-term stable operation.

3. Typical Applications

Air Cooler, with its highly efficient evaporative cooling characteristics, is widely used in the following scenarios:

Warehouses and Logistics Centers: Provides uniform cooling in large spaces, reducing quality loss due to high temperatures.

Computer Rooms and Data Centers: Assists air conditioning systems in reducing overall energy consumption through localized cooling, keeping equipment operating within safe temperature ranges.

Workshops and Production Lines: Provides a comfortable working environment for workers, improves production efficiency, and reduces machine failure rates due to overheating.

Fruit and Cold Storage: In environments requiring temperatures below 0°C, the Air Cooler, in conjunction with refrigeration units, achieves precise temperature control, extending the shelf life of agricultural products.

4. Key Advantages

Simple Structure and Easy Maintenance: No compressor or refrigerant circulation; fewer parts, low failure rate; routine maintenance only requires cleaning the heat exchanger and checking the water pump.

Low Energy Consumption: Single unit power is typically between tens and hundreds of watts, significantly reducing operating costs compared to the kilowatt-level power of traditional air conditioners.

Flexible Installation: No complex piping or exhaust systems are required; it can be placed directly near windows or vents, and relocation and relocation are very convenient.

Significant Cooling Effect: In relatively dry environments, evaporative cooling can lower air temperature by 10°C to 15°C and increase indoor relative humidity, improving comfort in dry climates.

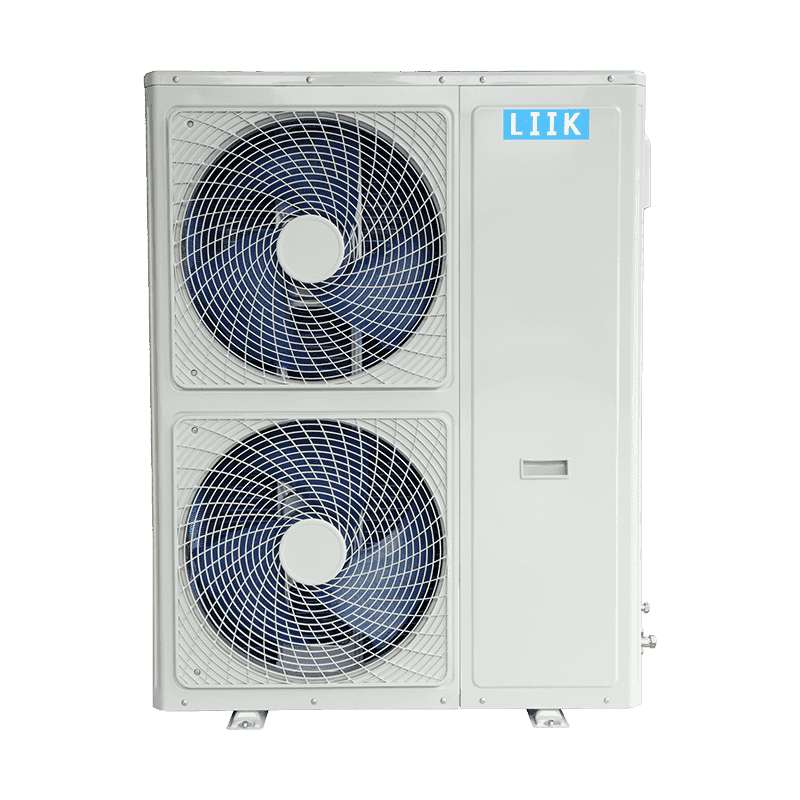

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español