Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

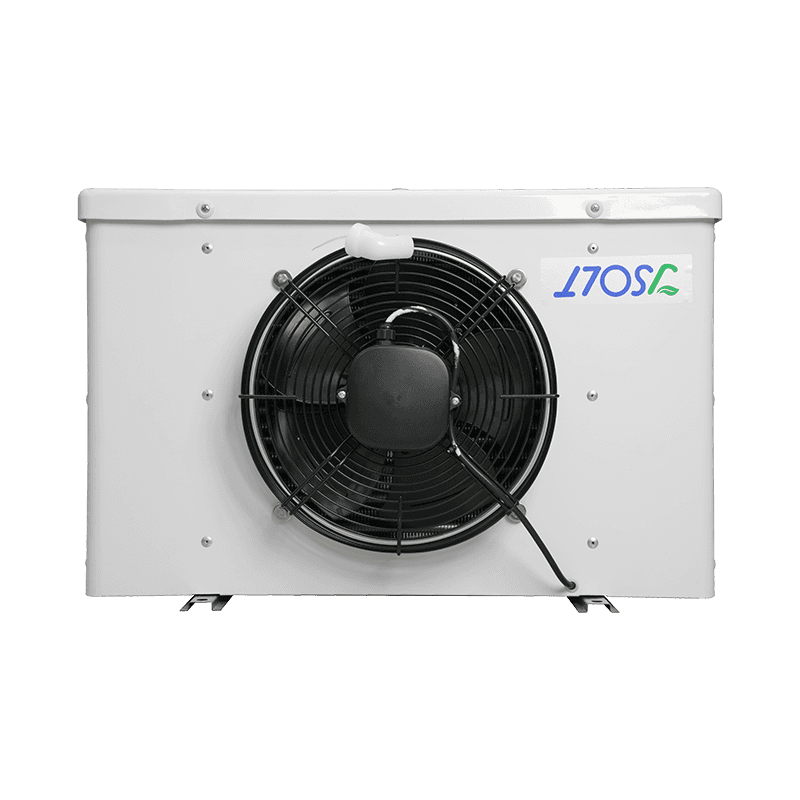

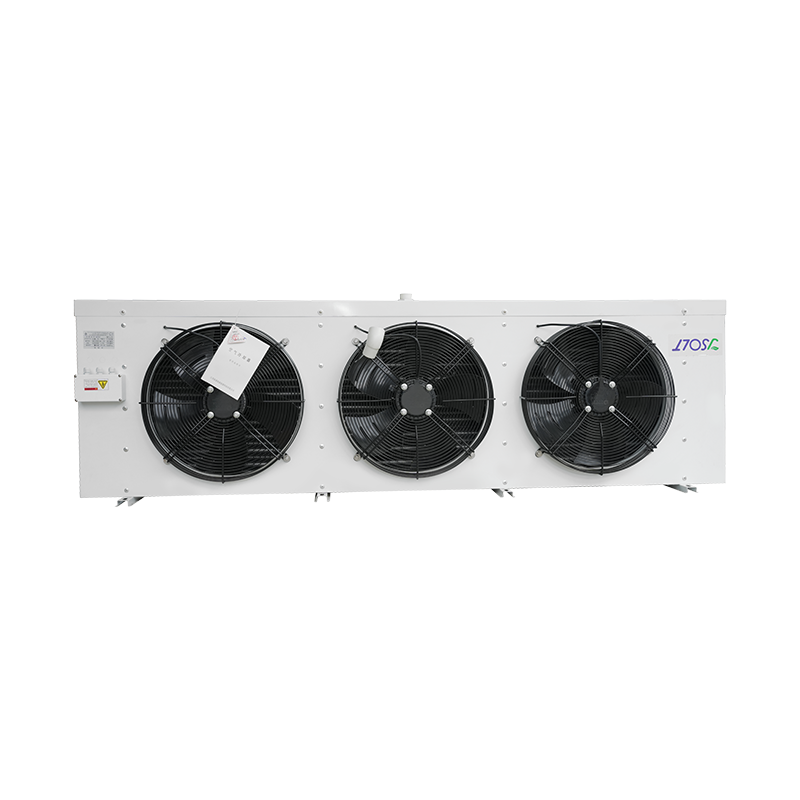

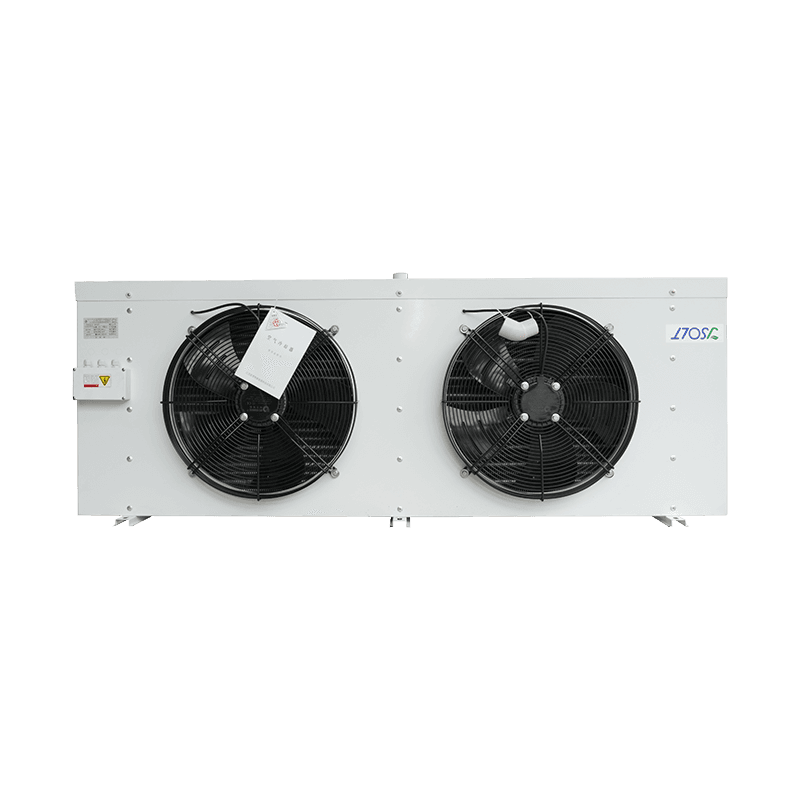

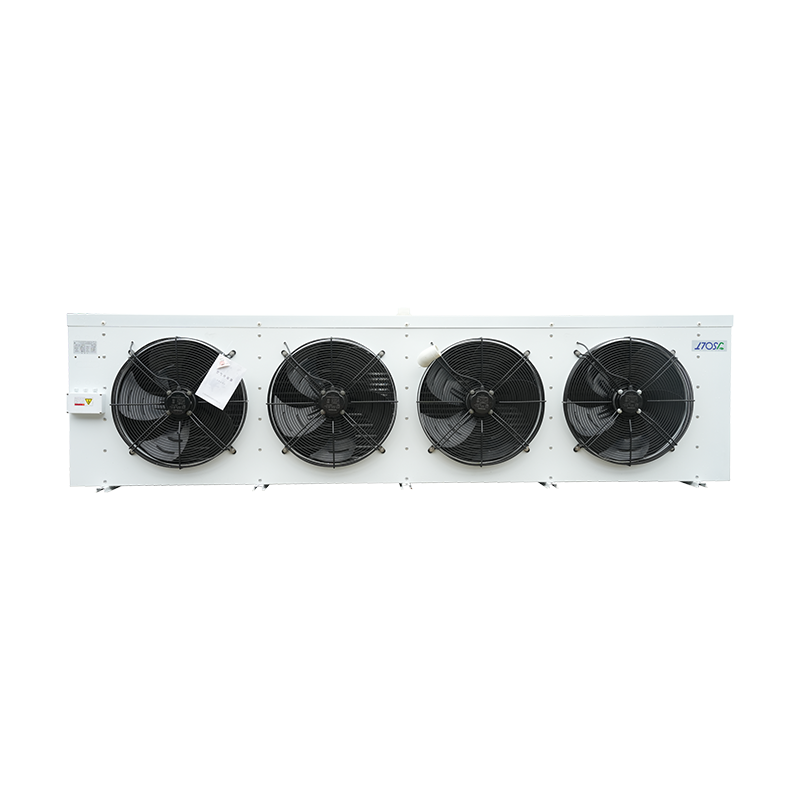

Why J2 Low Noise Air Cooler chooses high-quality copper tubes and aluminum fins as the core materials of high-efficiency chillers?

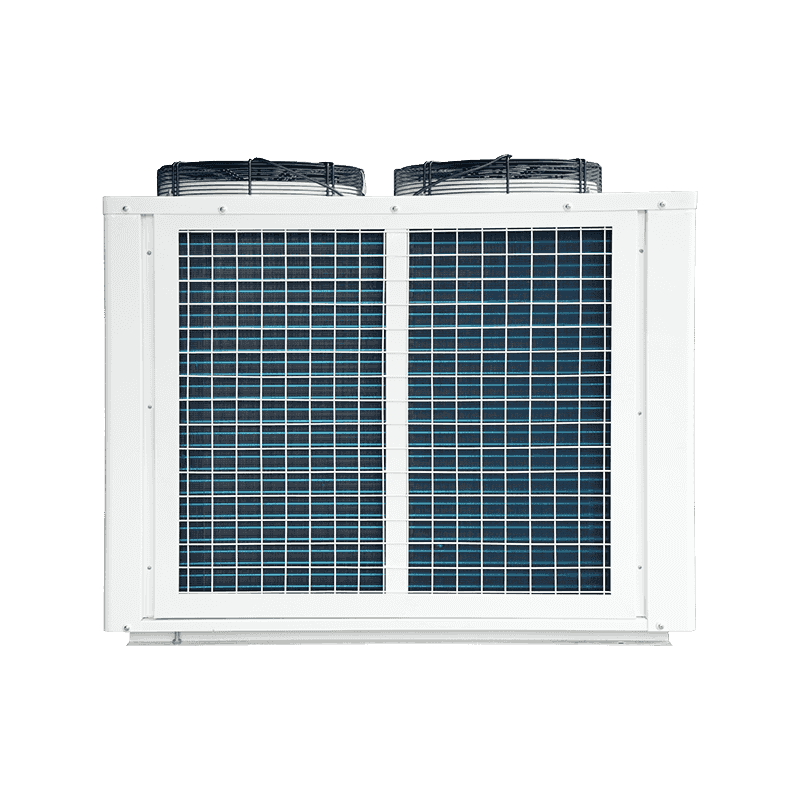

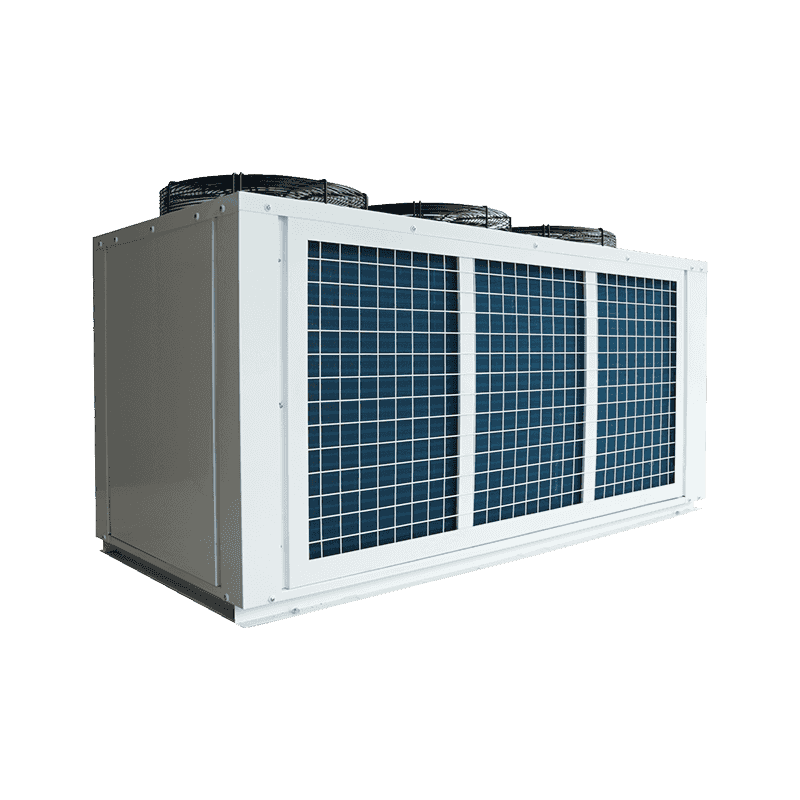

When manufacturing high-efficiency chillers, choosing the right materials is crucial, especially for copper tubes and aluminum fins. For J2 Low Noise Air Cooler, Air Cooler Manufacturer uses high-quality copper tubes with a diameter of 9.52 mm and special profile aluminum fins to ensure its excellent performance and durability.

Materials for manufacturing copper tubes and aluminum fins of high-efficiency chillers

Copper tube material: The copper tube of Low Noise Air Cooler uses high-quality copper material with a diameter of 9.52 mm. Copper has excellent thermal conductivity, which can transfer heat and improve heat exchange efficiency.

Aluminum fin material: The aluminum fin is designed with a special profile, which has good thermal conductivity, is lightweight and corrosion-resistant, and can ensure that the heat exchanger remains efficient and stable during long-term operation.

Why choose this material for copper tubes and aluminum fins for efficient chillers

High thermal conductivity of copper tubes: Selecting high-quality copper tubes as core components, based on their high thermal conductivity, can quickly transfer heat from the heat source to the cooling medium, improving heat exchange efficiency.

Special design of aluminum fins: The special profile design of aluminum fins can increase the heat exchange area, improve the heat exchange efficiency, and ensure that the equipment remains efficient during long-term operation.

Corrosion resistance of materials: Both copper tubes and aluminum fins have good corrosion resistance, can maintain stable performance in various environments, and extend the service life of the equipment.

Significance to Air Cooler Manufacturers

Improve product performance and reliability: Selecting these high-quality materials can improve product performance and reliability, and can meet customers' needs for efficient and low-noise cooling equipment.

Provide excellent cooling effect: By adopting these high-performance materials, J2 Low Noise Air Cooler can provide excellent cooling effects in various application scenarios, maintain low noise operation, and provide users with a more comfortable and quiet working environment.

Summary

Material selection basis: J2 Low Noise Air Cooler uses high-quality copper tubes and special profile aluminum fins based on their excellent performance in heat conduction, durability and reliability.

Careful selection by the manufacturer: Air Cooler Manufacturer ensures efficient operation and long-term stability of the product by carefully selecting and applying these materials, meeting the market demand for high-performance cooling equipment.

←

Why is Air Cooler Refrigeration & Heat Exchange Equipment efficient, stable and reliable in situations where air cooling is required?

→

Why does the Tecumseh Compressor Condensing Unit LBP use high corrosion resistance powder coated zinc?

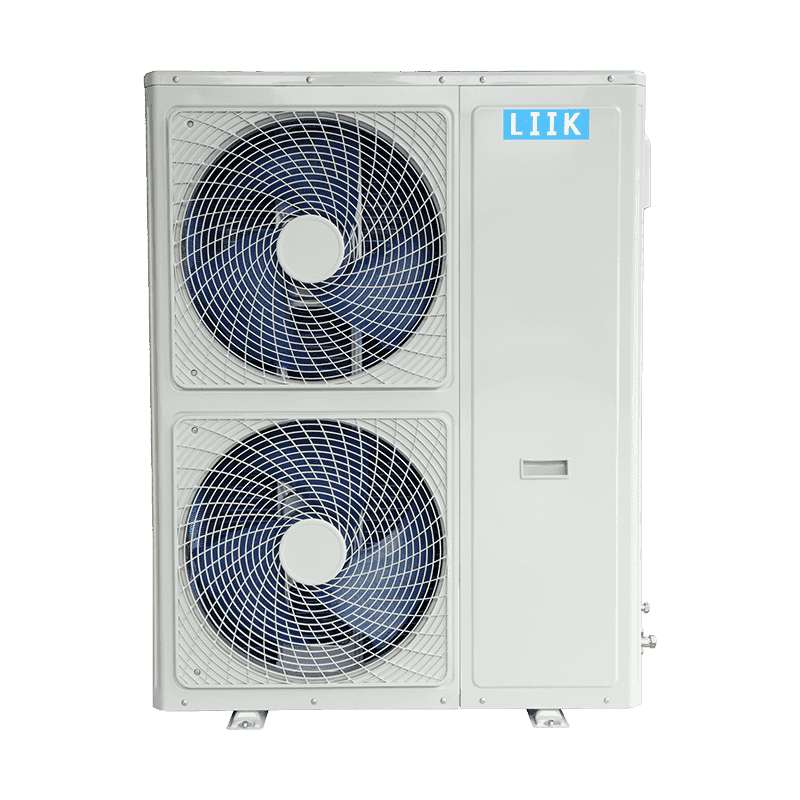

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español