Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

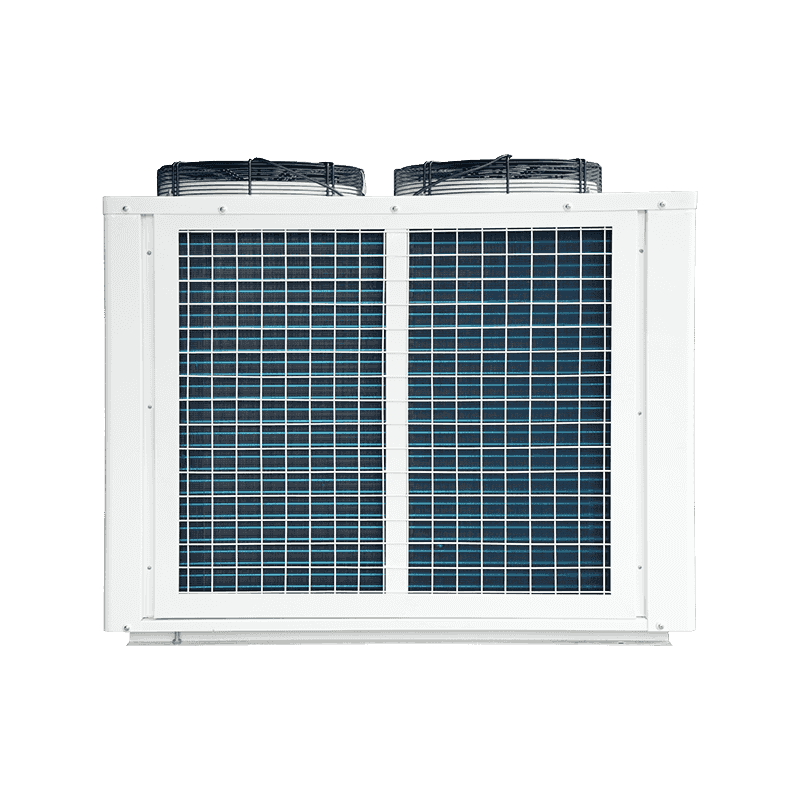

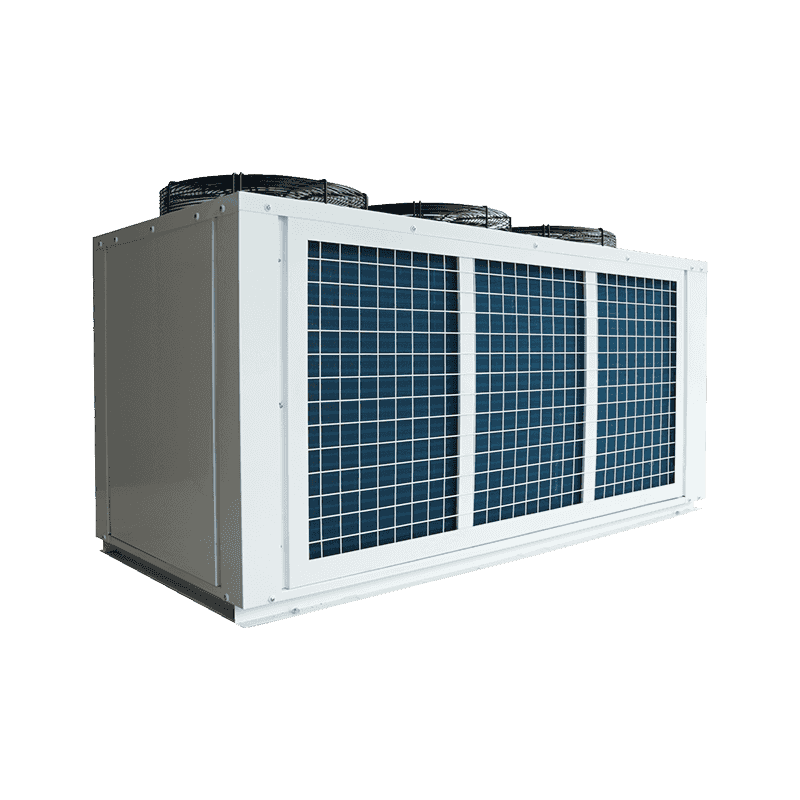

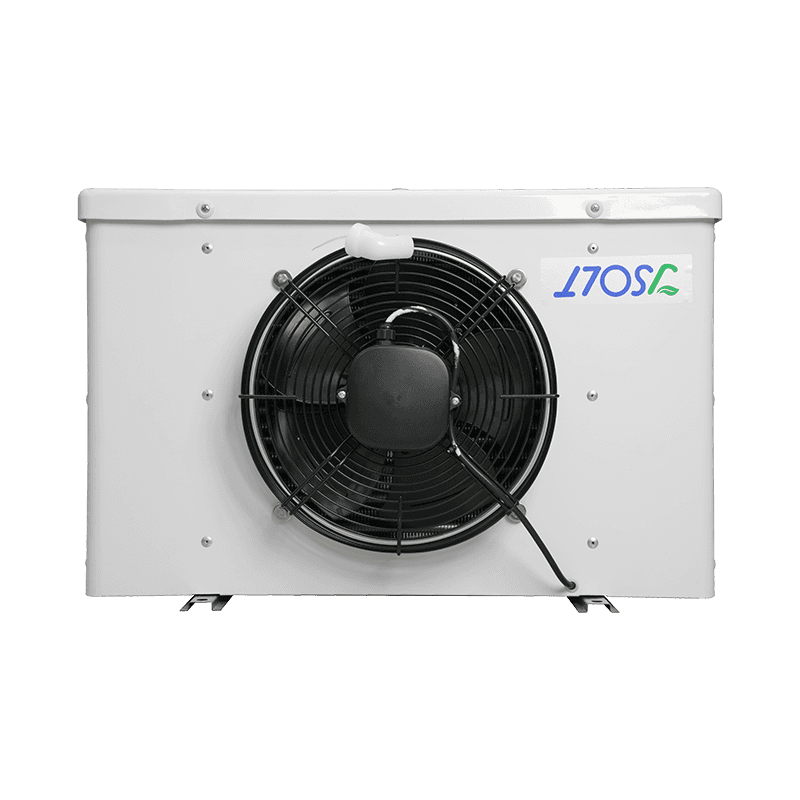

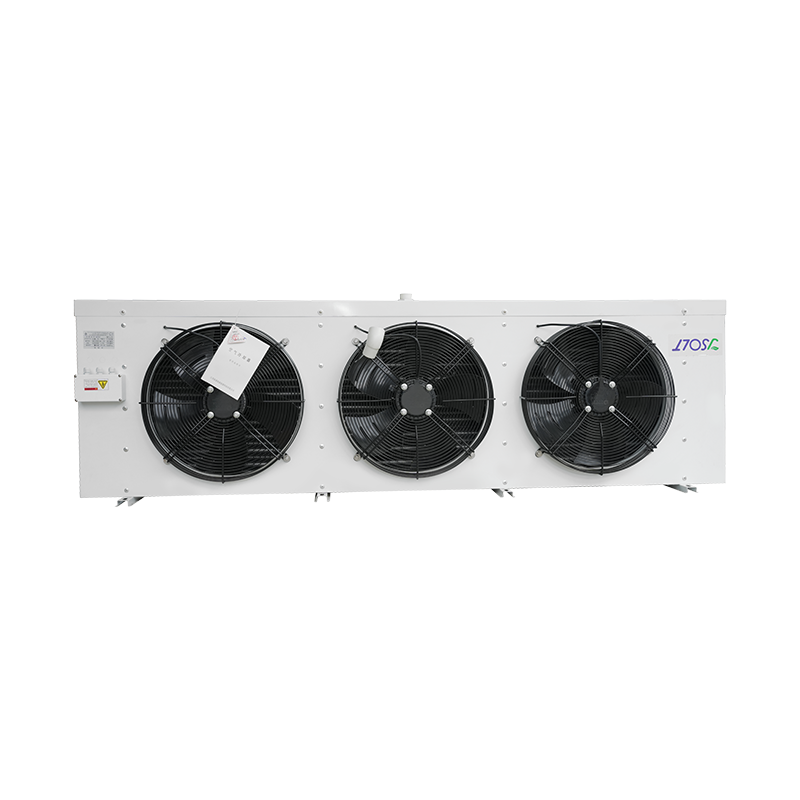

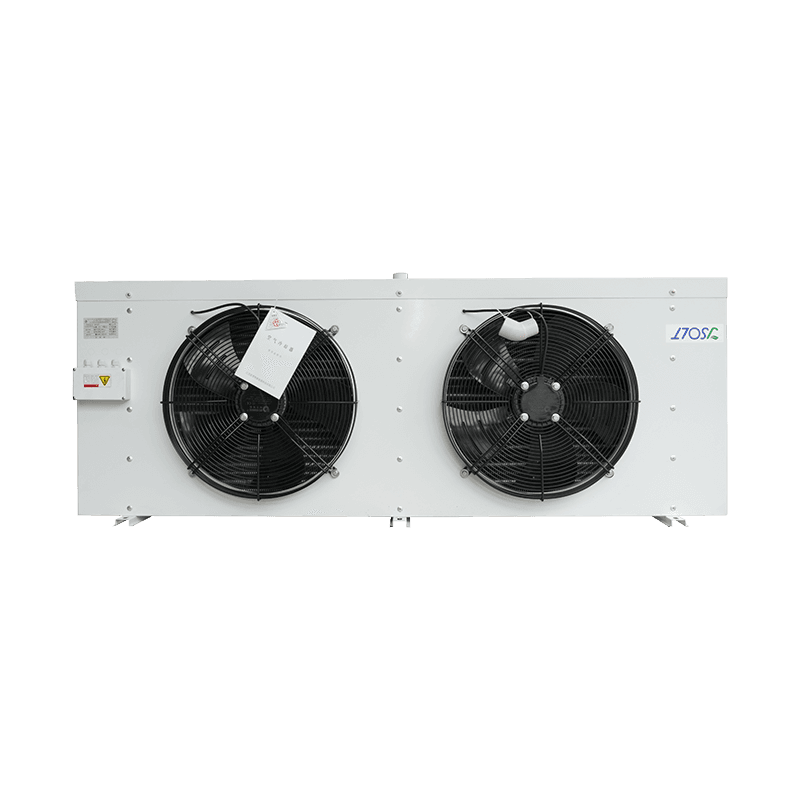

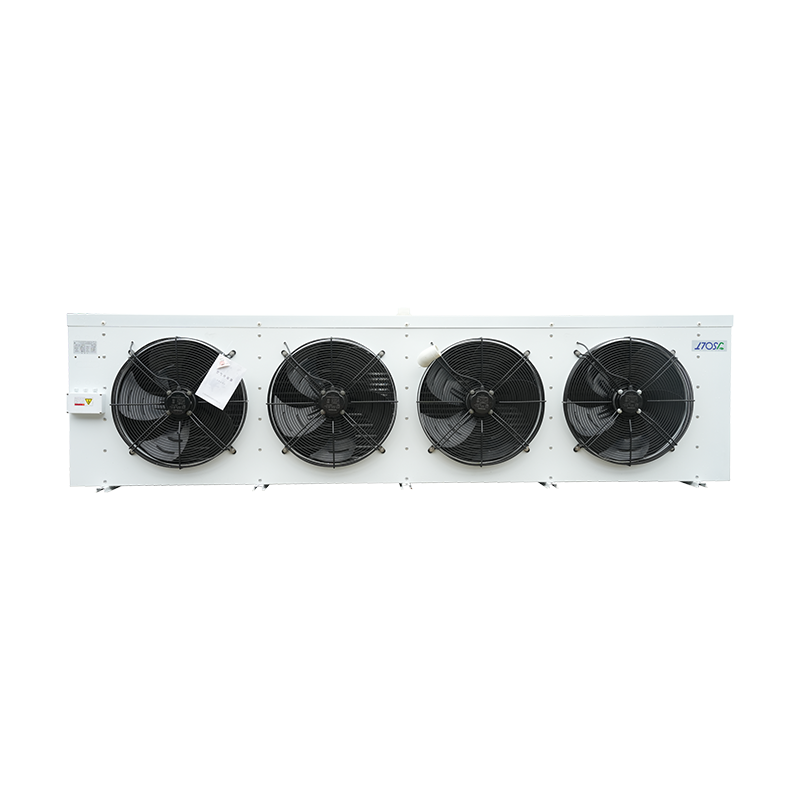

Why is Air Cooler Refrigeration & Heat Exchange Equipment efficient, stable and reliable in situations where air cooling is required?

What is air cooling design

1. High-efficiency coil construction

Core material: In Air Cooler Refrigeration & Heat Exchange Equipment, the high-efficiency coil is made of high-quality copper tubes of Ф12 mm and special profile aluminum fins. It ensures efficient heat conduction and heat exchange performance, and enhances the durability and reliability of the equipment.

Heat exchange efficiency: The combination of copper tubes and aluminum fins makes the heat exchange process more efficient, which can quickly transfer the heat in the refrigerant to the air and achieve rapid cooling. It has advantages in Refrigeration System and can meet various refrigeration needs.

Cleaning test: The heat exchanger is cleaned and tested at a pressure of 30 bars to ensure the efficient operation and long-term reliability of the equipment. This test improves the heat exchange efficiency of the equipment and reduces operating costs.

2. High-performance shell design

Material selection: The shell of Air Cooler Refrigeration & Heat Exchange Equipment is made of white powder-coated aluminum, which has high corrosion strength and impact resistance and can withstand the influence of various harsh environments. This shell material extends the service life of the equipment and ensures the cleanliness and safety of the equipment during operation.

Environmental characteristics: The white powder-coated aluminum shell does not produce polluting debris, ensuring the cleanliness and safety of the equipment during operation. It has advantages in the Refrigeration System and can meet various environmental protection requirements.

Aesthetics: The white powder-coated aluminum shell has excellent performance and beautiful appearance, which can be coordinated with various environments and enhance the overall image of the equipment.

3. High-quality fan motor

High safety standards: All fan motors of Air Cooler Refrigeration & Heat Exchange Equipment use high-quality axial flow fan motors that meet high safety standards, which perfectly match the unit housing with anti-vibration system. It improves the operating efficiency of the equipment, reduces noise and vibration, and provides users with a more comfortable and quiet environment.

Operation efficiency: The high-quality axial flow fan motor can provide strong wind force, ensure the circulation of air inside the equipment, and realize efficient heat exchange process. It has advantages in the Refrigeration System and can meet various refrigeration needs.

Anti-vibration system: The unit housing with anti-vibration system can reduce the vibration of the equipment during operation, extend the service life of the equipment, and reduce maintenance costs.

4. Defrost heating function

Heating element: Air Cooler Refrigeration & Heat Exchange Equipment uses stainless steel heating elements covered by aluminum tubes, which are located in the fin group and the water tray, which can prevent the equipment from frosting in low temperature environments and ensure the long-term stable operation of the equipment.

Anti-frost effect: The stainless steel heating element can provide stable heat to ensure that the equipment will not frost in low temperature environments and ensure the normal operation of the equipment. It has advantages in the Refrigeration System and can meet various refrigeration needs.

Long-term reliability: The defrost heating function improves the operating efficiency of the equipment, extends the service life of the equipment, and reduces maintenance costs.

Why is air cooling refrigeration and heat exchange equipment suitable for occasions requiring air cooling

1. Efficient heat exchange performance

Efficient coil design: Air Cooler Refrigeration & Heat Exchange Equipment usually adopts an efficient coil design to ensure efficient heat conduction and heat exchange performance, which can quickly transfer the heat in the refrigerant to the air to achieve rapid refrigeration. In occasions where air cooling is required, this efficient heat exchange performance can ensure that the equipment can operate stably under various environmental conditions.

Optimized fan system: The high-quality axial fan motor equipped with the equipment can provide strong wind force, ensure the circulation of air inside the equipment, and realize efficient heat exchange process. It improves the operating efficiency of the equipment, reduces noise and vibration, and provides users with a comfortable and quiet environment.

2. Adapt to various environmental conditions

High-performance shell design: Air Cooler Refrigeration & Heat Exchange Equipment adopts high-performance shell design, such as white powder-coated aluminum shell, which has high corrosion strength and impact resistance, and can withstand the influence of various harsh environments. It extends the service life of the equipment and ensures the cleanliness and safety of the equipment during operation.

Defrost heating function: The equipment is usually equipped with a defrost heating function, which can prevent the equipment from frosting in a low temperature environment and ensure the normal operation of the equipment. This design has advantages in occasions where air cooling is required and can meet various refrigeration needs.

3. Low operating cost and high reliability

Energy-saving design: Air Cooler Refrigeration & Heat Exchange Equipment can achieve low energy consumption and reduce operating costs through optimized heat exchange mechanism and efficient fan system. In occasions where air cooling is required, this energy-saving design can bring significant economic benefits to users.

Long-term reliability: The equipment is made of high-quality materials and advanced technology, and is stable and reliable, and can operate stably for a long time. Carefully selected electrical components and wiring materials can ensure the stability and reliability of the equipment in long-term operation, reducing the failure rate and maintenance cost of the equipment.

←

How to evaluate and understand the main features of medium and low temperature commercial refrigeration condensing units and their refrigeration effect and stability?

→

Why J2 Low Noise Air Cooler chooses high-quality copper tubes and aluminum fins as the core materials of high-efficiency chillers?

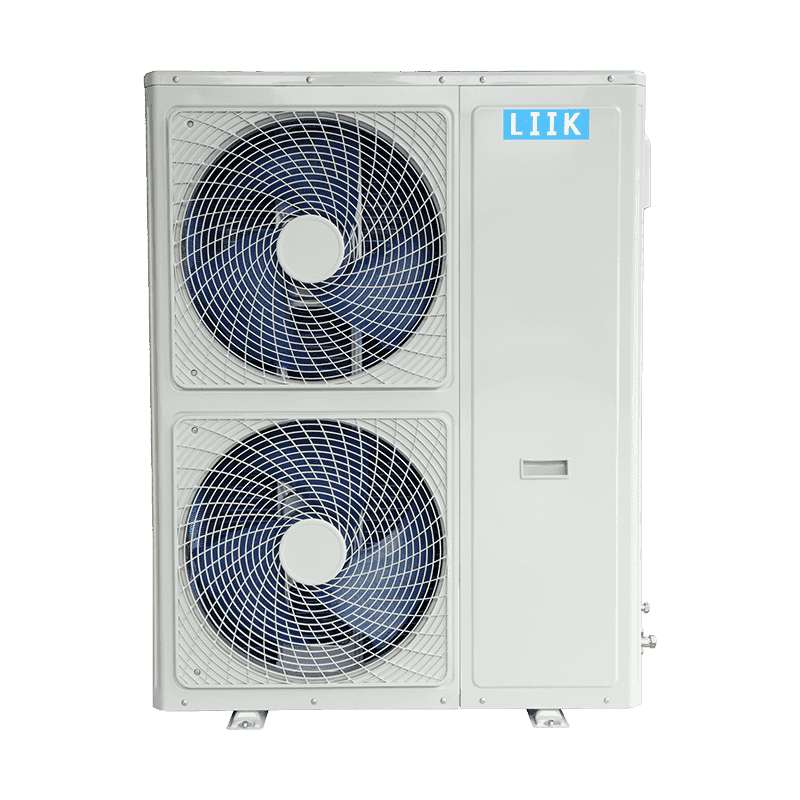

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español