Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

Why is the crankcase heater so important in Medium And Low Temperature Commercial Refrigeration Condensing Units?

1. Ensure the fluidity of the lubricating oil

Challenges in low temperature environments: In the field of medium and low temperature commercial refrigeration, Medium And Low Temperature Commercial Refrigeration Condensing Units often operate in low temperature environments. In such an environment, the viscosity of the lubricating oil will increase significantly and the fluidity will decrease. This will cause the compressor to not be fully lubricated at startup, causing problems such as increased wear and reduced efficiency.

The role of the crankcase heater: The crankcase heater heats the lubricating oil to keep it within the appropriate temperature range to ensure its fluidity.

2. Prevent moisture condensation

The impact of moisture on the refrigeration system: In the refrigeration system, the presence of moisture can cause serious damage to the system. Moisture may cause corrosion, ice blockage and other problems, which in turn affect the normal operation and service life of the system.

The protective role of the crankcase heater: The crankcase heater can effectively remove moisture from the lubricating oil by heating it.

3. Improve operating efficiency and extend service life

Improvement of operating efficiency: Crankcase heaters improve the operating efficiency of Medium And Low Temperature Commercial Refrigeration Condensing Units by ensuring the normal flow of lubricating oil and preventing water condensation. The compressor operates in an environment with full lubrication and no water interference, and can complete the refrigeration task more efficiently.

Extend equipment life: The use of crankcase heaters reduces the wear of the compressor and the damage to the refrigeration system, thereby extending the service life of the equipment.

4. Reduce maintenance costs

Reduce maintenance requirements: Since the crankcase heater can effectively prevent lubricating oil solidification and water condensation, it reduces the failure and maintenance requirements caused by poor lubrication and water damage. In this way, the maintenance cost of the equipment is greatly reduced, and the economy of the equipment is improved.

Simplify maintenance work: The use of crankcase heaters simplifies the maintenance work of the equipment. Maintenance personnel do not need to frequently check and deal with problems such as lubricating oil solidification and water condensation, saving time and energy and improving maintenance efficiency.

←

Why Does the High Power Industrial DD Air Cooler Have Significant Energy Efficiency Advantages?

→

How does the LKPG Series Refrigeration Condensing Unit function within a refrigeration system?

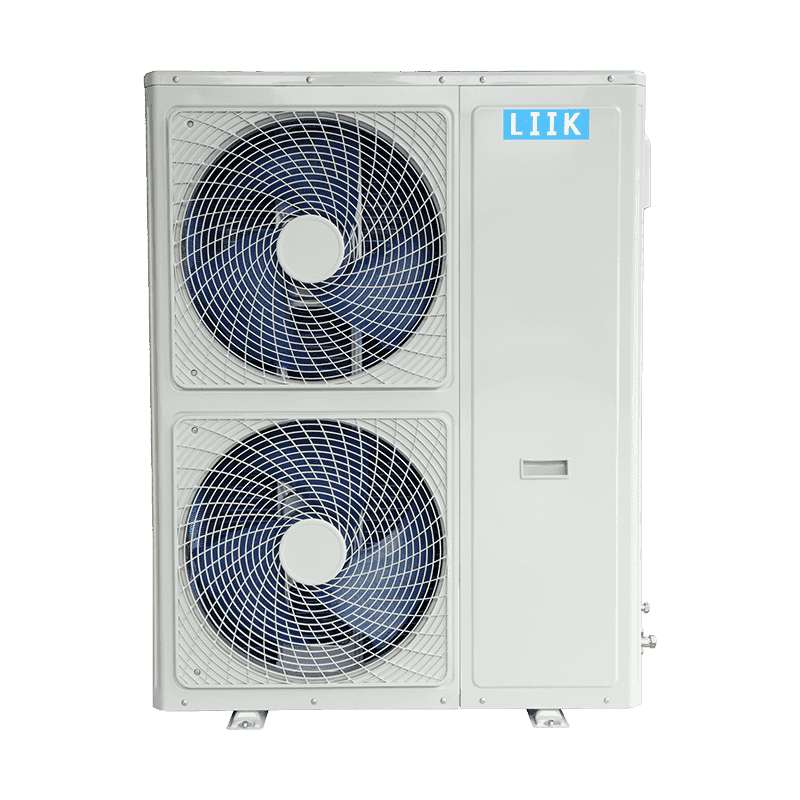

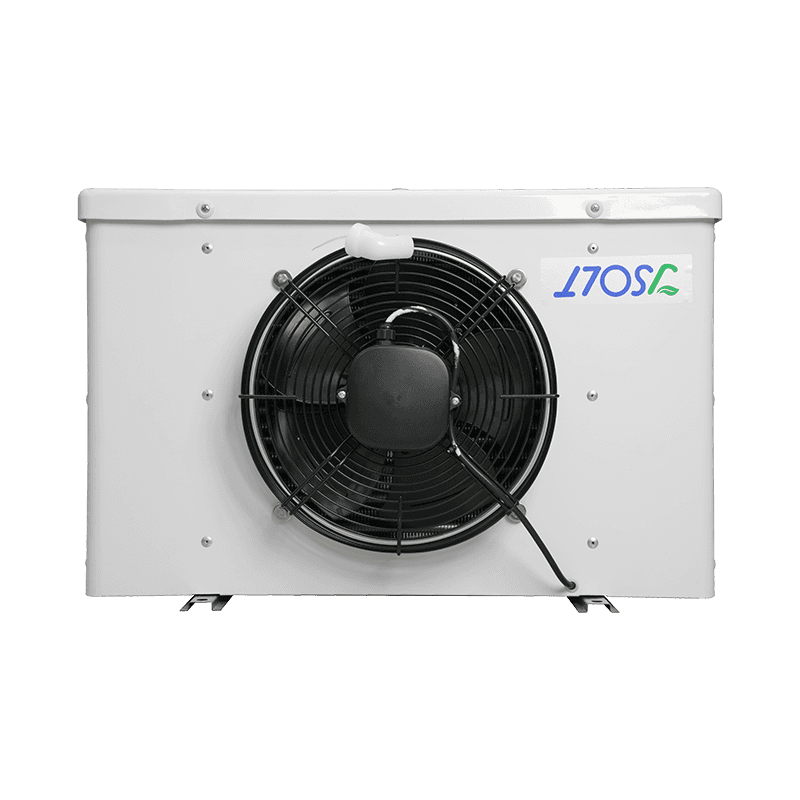

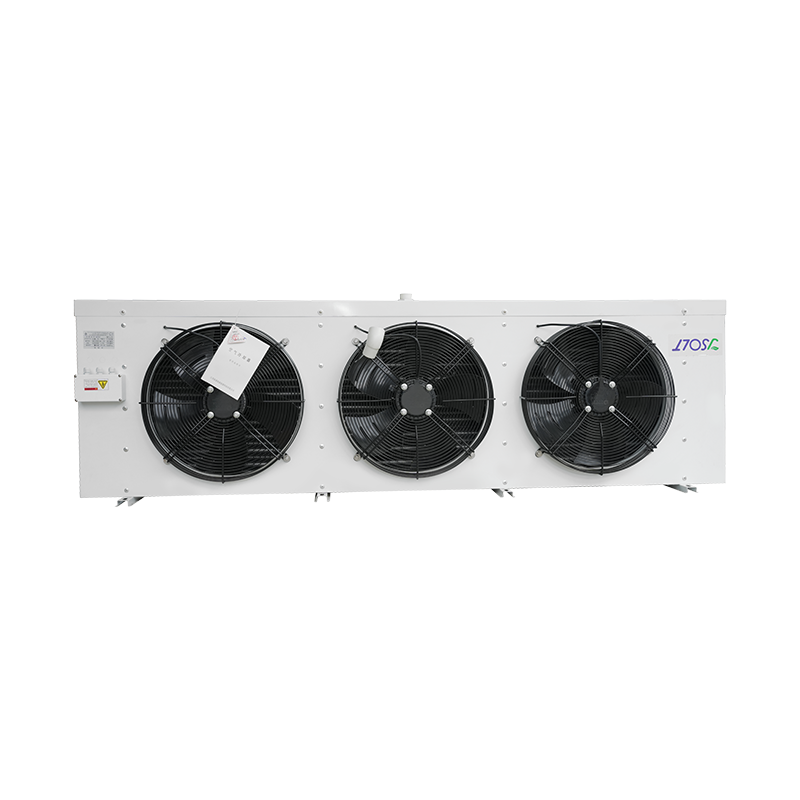

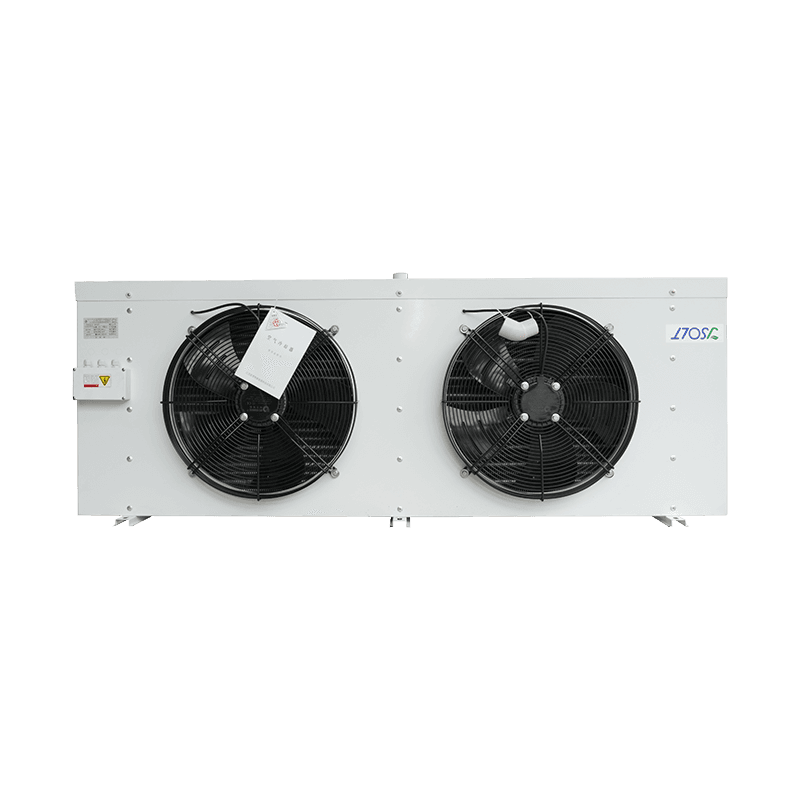

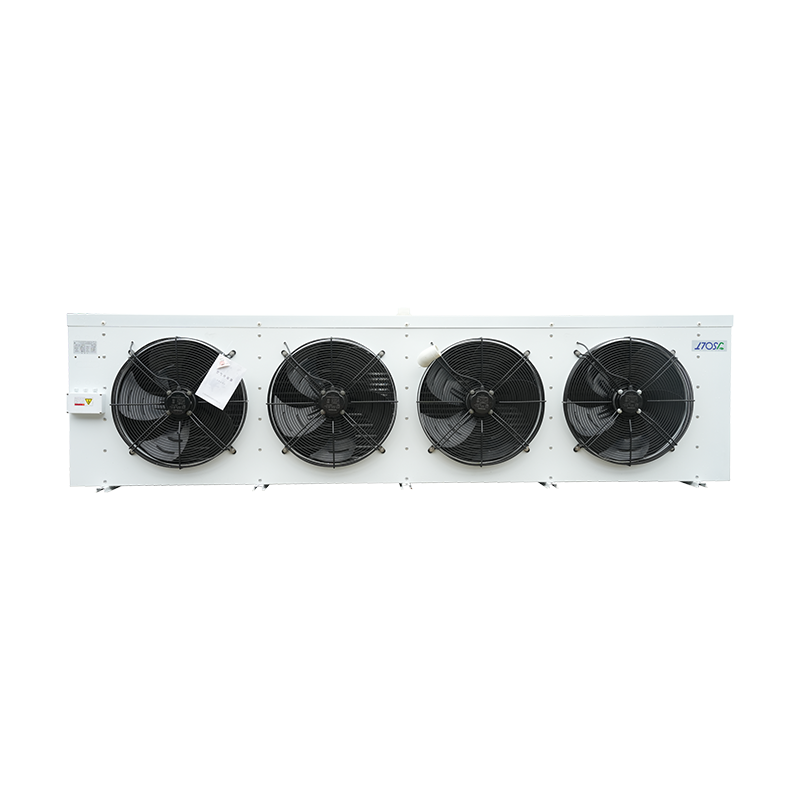

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español