Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

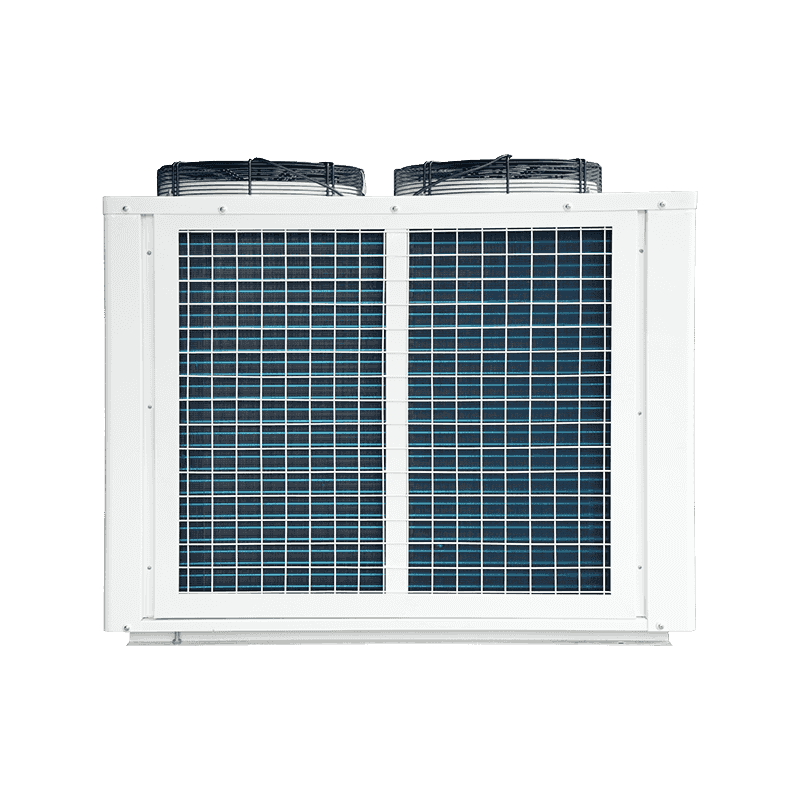

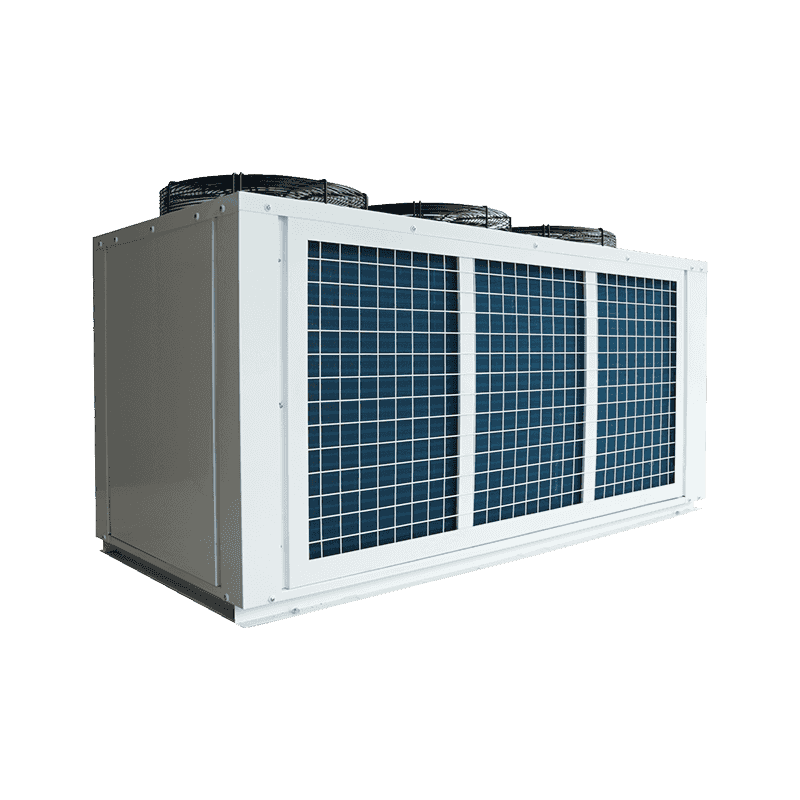

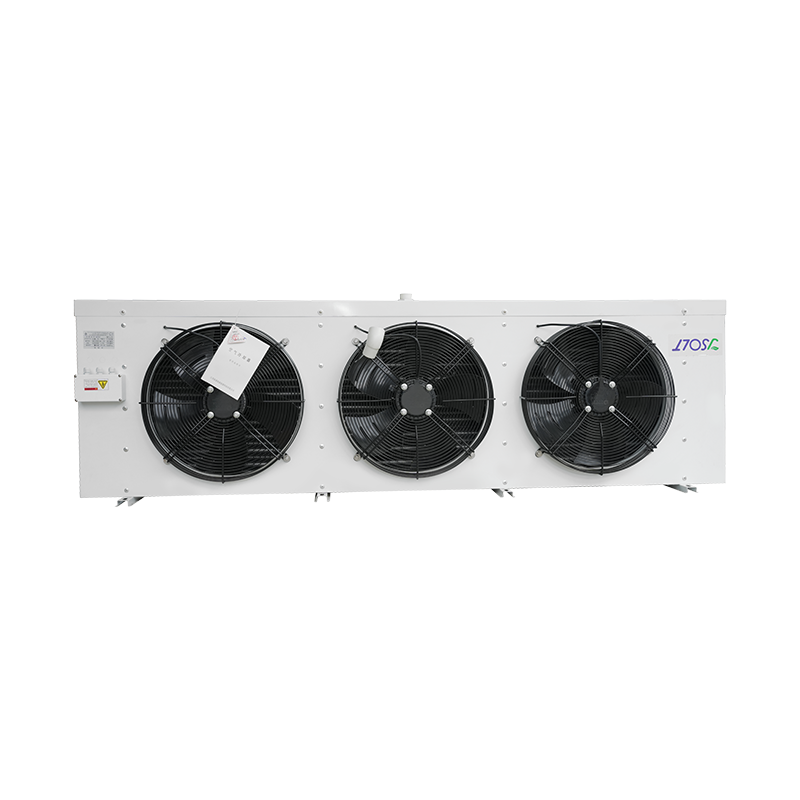

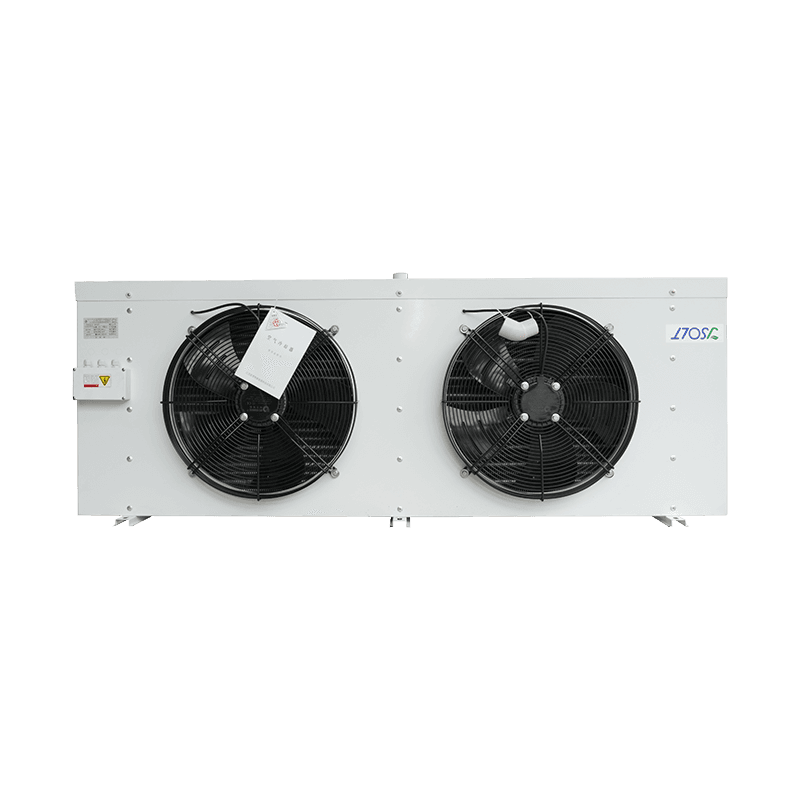

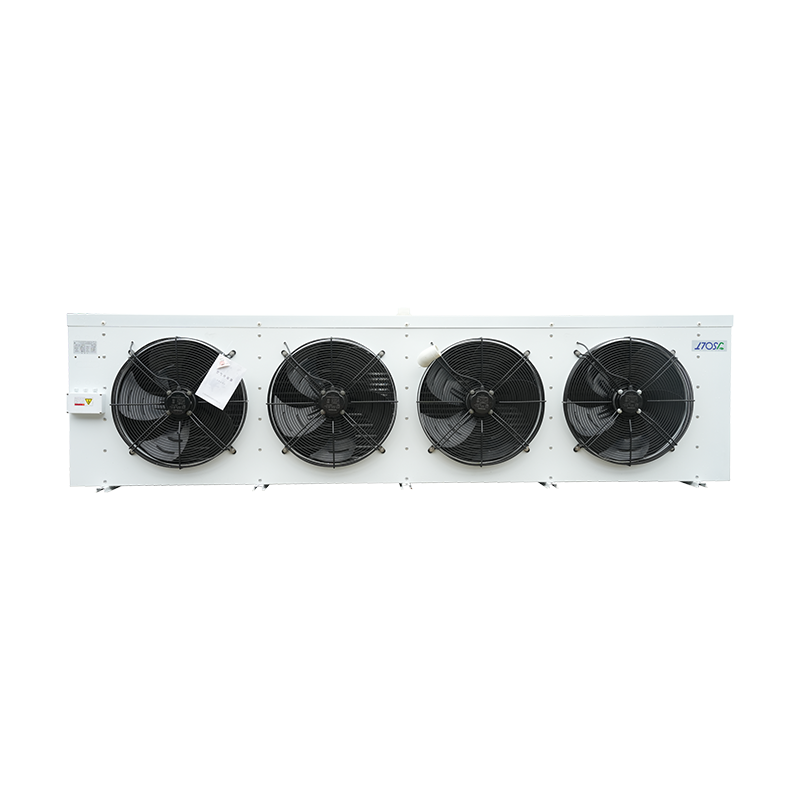

Why Does the High Power Industrial DD Air Cooler Have Significant Energy Efficiency Advantages?

1. Advanced Heat Exchange Technology and Optimized Design

The High Power Industrial DD Air Cooler employs advanced heat exchange technology, which is one of the key factors contributing to its significant energy efficiency advantages. Through optimized heat exchange design, the cooler can efficiently transfer heat generated by industrial equipment, ensuring that the equipment operates at an appropriate temperature. This efficient heat exchange process reduces energy loss, thereby improving overall energy efficiency. Additionally, the optimized design ensures that the cooler maintains stable performance under various operating conditions, further enhancing its energy efficiency.

2. High-Performance Fan System and Low-Energy Operation

The High Power Industrial DD Air Cooler is equipped with a high-performance fan system, which is another important advantage in terms of energy efficiency. These fans are meticulously designed to provide strong airflow at low energy consumption, effectively expelling heat. The efficient operation of the fans not only reduces energy consumption but also minimizes noise and vibration, further improving the operational efficiency and stability of the equipment. By adopting advanced fan technology, the High Power Industrial DD Air Cooler can ensure cooling effectiveness while minimizing energy consumption, achieving the goal of energy conservation and emission reduction.

3. Intelligent Control System and Precise Regulation

The High Power Industrial DD Air Cooler also features an intelligent control system, which is another critical factor contributing to its significant energy efficiency advantages. This intelligent control system can automatically adjust the cooling power based on actual operating conditions, ensuring that the cooler maintains optimal energy efficiency under different operating conditions. By precisely controlling the cooling power, the High Power Industrial DD Air Cooler can avoid unnecessary energy waste, further enhancing its energy efficiency. Additionally, the intelligent control system can continuously monitor the operating status of the equipment, promptly identify and resolve potential issues, ensuring long-term stable operation of the equipment.

4. High-Quality Materials and Advanced Manufacturing Processes

The High Power Industrial DD Air Cooler uses high-quality materials and advanced manufacturing processes, which are another important factors contributing to its significant energy efficiency advantages. These materials and processes not only extend the service life of the equipment but also reduce the frequency of maintenance and replacement, further lowering operating costs and energy consumption. By adopting high-quality materials and advanced manufacturing processes, the High Power Industrial DD Air Cooler can provide efficient and reliable cooling solutions in industrial applications, helping users achieve the goal of energy conservation and emission reduction.

←

How to ensure that the Low Noise Evaporator Air Conditioner shell has high corrosion strength and impact resistance?

→

Why is the crankcase heater so important in Medium And Low Temperature Commercial Refrigeration Condensing Units?

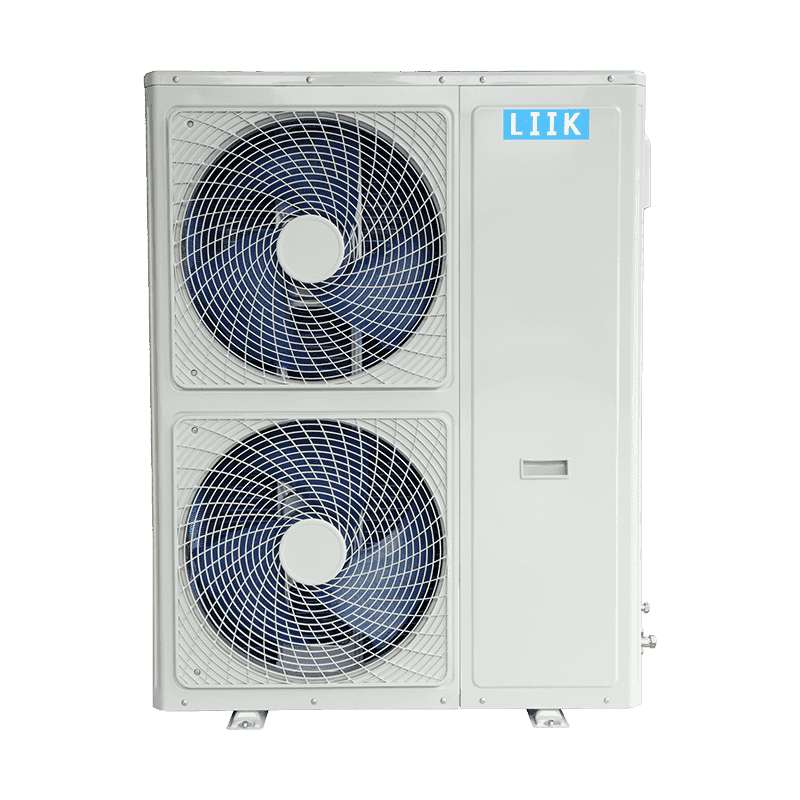

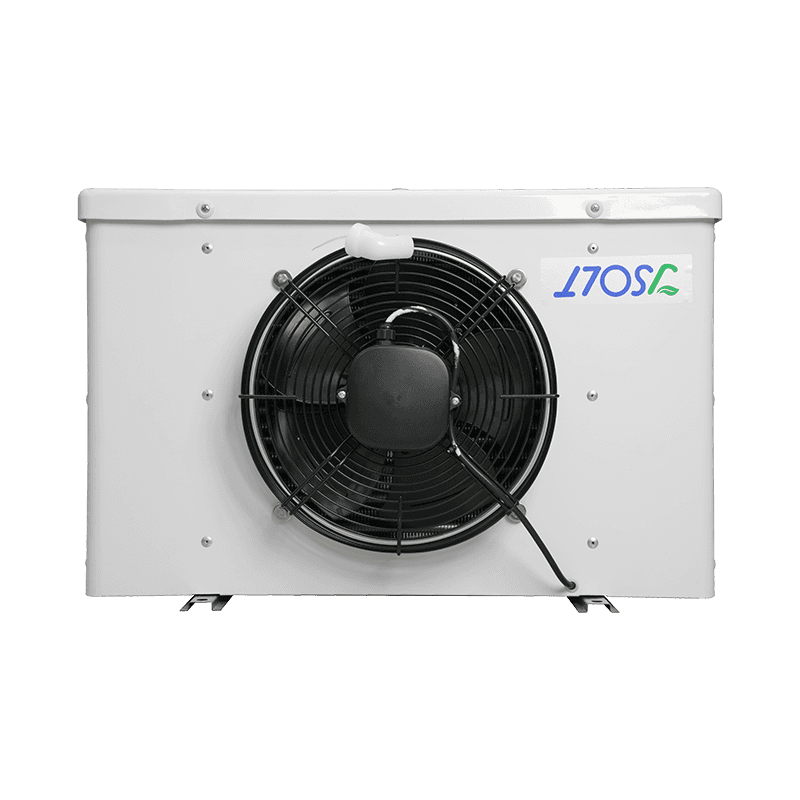

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español