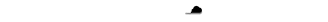

Product Series

Compact FHKT Evaporator

General features:

The high efficient coils are made from high quality copper tube Ф12mm(FHKT 250), Ф15mm(FHKT 300) and special profile aluminium fins.

Heat exchangers are supplied clean and tested under apressure of 30 bars.

The casing:

White powder coated aluminium, high corrosion strength, impact resistance, and does not produce polluting debris.

The fan motors:

All with high quality axial fan motors with high sagety standatds fitted well to the unit casing with an anti-vibration system.

Defrost heating:

Provided by stainless steel heater elements covered by the aluminium tubes,located in the finned pack and in the drain pan.

Electrical parts and wiring:

Are connected to an earth terminal, carried out in junction box with access hiles equipped with water-proof cable grands. All materials are selected carefully for long-term reliability.

- Product Description

+86-18082061600

+86-18082061600

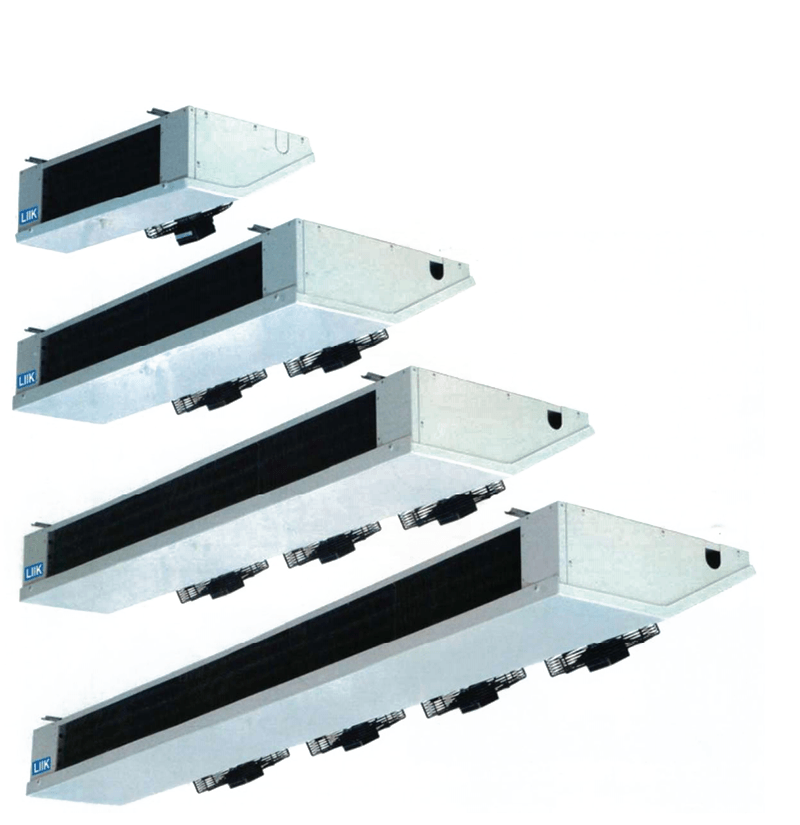

Model classification:

FHKT 3002 20 7D

Defrost E Heater

Fin Spacing (mm)

Surface(m²)

FanФ(mm)"N°

Series

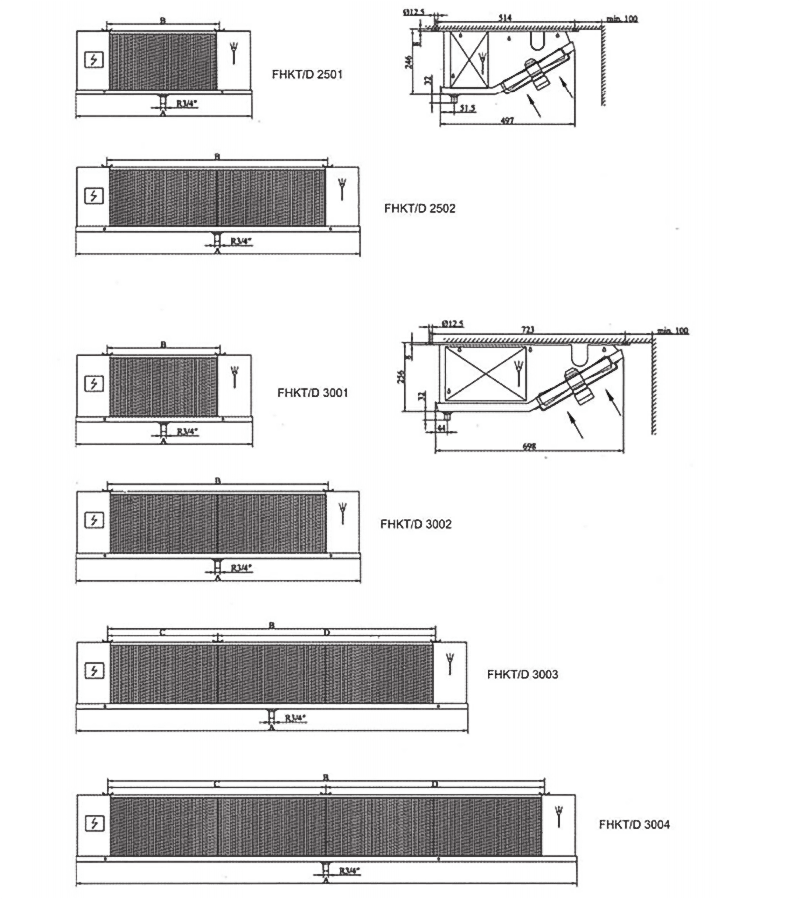

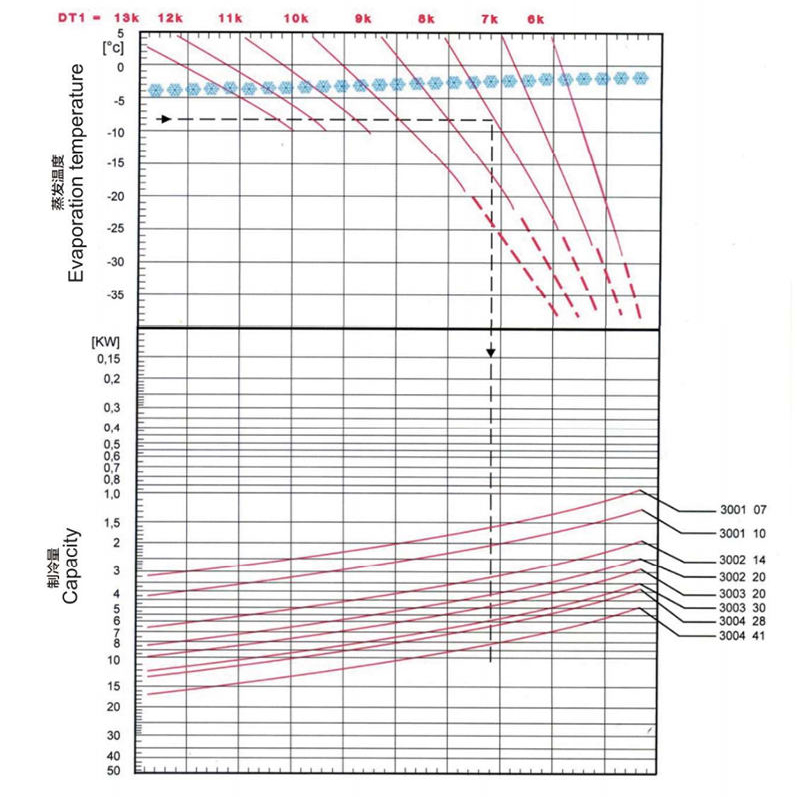

Selection Diagram

FHKT 4.5/D Series

FHKT series Evaporator

Fin spacing 7 mm, with heater, Rt≥-18℃

|

Model |

Capacity R404A/R507A(kw) |

Surface(m²) |

Tube Volume(dm³) |

Dimensions(mm) |

N.W.(kg) |

Connection(∮mm) |

|||||

|

t=-8℃ |

f =-25℃ |

||||||||||

|

A |

B |

C |

D |

Inlet |

outlet |

||||||

|

DTI=8K |

DTI=7K |

||||||||||

|

FHVT 3001 07 7D |

1.58 |

1.24 |

7 |

1.9 |

915 |

620 |

19 |

12 |

15 |

||

|

FHVT 3001 10 7D |

2.04 |

1.6 |

10 |

2.9 |

915 |

620 |

22 |

12 |

15 |

||

|

FHVT 3002 14 7D |

3.16 |

2.48 |

14 |

3.5 |

1515 |

1222 |

32 |

12 |

15 |

||

|

FHVT 3002 20 7D |

4.08 |

3.2 |

20 |

5.4 |

1515 |

1222 |

38 |

12 |

22 |

||

|

FHVT 3003 20 7D |

4.75 |

3.72 |

20 |

5.2 |

2117 |

1823 |

620 |

1203 |

44 |

12 |

22 |

|

FHVT 3003 30 7D |

5.83 |

4.57 |

30 |

7.8 |

2117 |

1823 |

620 |

1203 |

53 |

12 |

22 |

|

FHVT 3004 28 7D |

6.33 |

4.96 |

28 |

6.8 |

2717 |

2425 |

1222 |

1203 |

58 |

12 |

22 |

|

FHVT 3004 41 7D |

8.17 |

6.39 |

41 |

10.3 |

2717 |

2425 |

1222 |

1203 |

69 |

12 |

28 |

Electric data

|

Mold |

Axial Fans |

Electric Defrost |

||||||||

|

Diameter(∮mm) |

N⁰ |

Voltage(V,50/60Hz) |

Power(W) |

Current(A) |

Air Flow (m³/h) |

Throw(m) |

Coil(W) |

Drain Pan (W) |

Total(W) |

|

|

FHKT 3001 07 7D |

300 |

1 |

~220 |

87/105 |

0.44/0.48 |

1970 |

9 |

2x570 |

1x570 |

1710 |

|

FHKT 3001 10 7D |

300 |

1 |

~220 |

87/105 |

0.44/0.48 |

1810 |

8 |

2x570 |

1x570 |

1710 |

|

FHKT 3002 14 7D |

300 |

2 |

~220 |

174/210 |

0.88/0.96 |

3940 |

11 |

2x1030 |

1x1030 |

3090 |

|

FHKT 3002 20 7D |

300 |

2 |

~220 |

174/210 |

0.88/0.96 |

3620 |

10 |

2x1030 |

1x1030 |

3090 |

|

FHKT 3003 20 7D |

300 |

3 |

~220 |

261/315 |

1.32/1.44 |

5910 |

13 |

2x1500 |

1x500 |

4500 |

|

FHKT 3003 30 7D |

300 |

3 |

~220 |

261/315 |

1.32/1.44 |

5430 |

12 |

2x1500 |

1x1500 |

4500 |

|

FHKT 3004 28 7D |

300 |

4 |

~220 |

348/420 |

1.76/1.92 |

7880 |

15 |

2x2000 |

1x2000 |

6000 |

|

FHKT 3004 41 7D |

300 |

4 |

~220 |

348/420 |

1.76/1.92 |

7240 |

14 |

2x2000 |

1x2000 |

6000 |

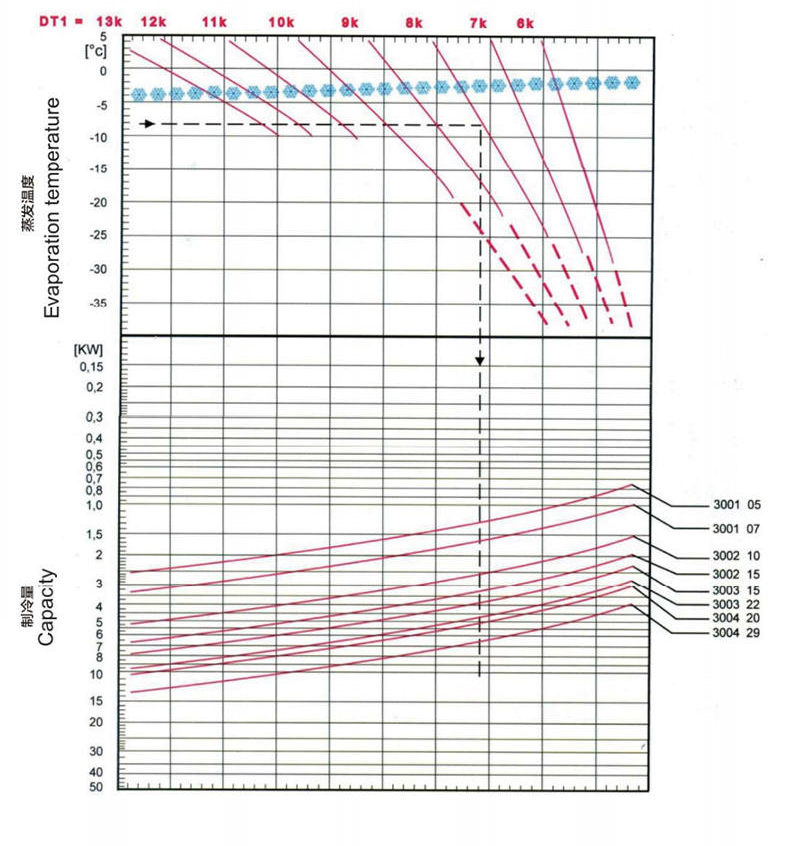

Selection Diagram

FHKT 7/D Series

FHKT series Evaporator

Fin spacing 10 mm, with heater, Rt≥-25℃

|

Model |

Capacity R404A/R507A(kw) |

Surface(m²) |

Tube Volume(dm³) |

Dimensions(mm) |

N.W.(kg) |

Connection(∮mm) |

|||||

|

t=-8℃ |

f =-25℃ |

||||||||||

|

A |

B |

C |

D |

Inlet |

outlet |

||||||

|

DTI=8K |

DTI=7K |

||||||||||

|

FHKT 3001 05 10D |

1.28 |

1 |

5 |

1.9 |

915 |

620 |

18 |

12 |

15 |

||

|

FHKT 3001 07 10D |

1.65 |

1.29 |

7 |

2.9 |

915 |

620 |

- |

- |

20 |

12 |

15 |

|

FHKT 3002 10 10D |

2.55 |

2 |

10 |

3.5 |

1515 |

1222 |

- |

- |

29 |

12 |

15 |

|

FHKT 3002 15 10D |

3.29 |

2.58 |

15 |

5.4 |

1515 |

1222 |

- |

- |

34 |

12 |

22 |

|

FHKT 3003 15 10D |

3.83 |

3 |

15 |

5.2 |

2117 |

1823 |

620 |

1203 |

40 |

12 |

22 |

|

FHKT 3003 22 10D |

4.94 |

3.87 |

22 |

7.8 |

2117 |

1823 |

620 |

1203 |

47 |

12 |

22 |

|

FHKT 3004 20 10D |

5.1 |

4 |

20 |

6.8 |

2717 |

2425 |

1222 |

1203 |

52 |

12 |

22 |

|

FHKT 3004 29 10D |

6.58 |

5.16 |

29 |

10.3 |

2717 |

2425 |

1222 |

1203 |

61 |

12 |

28 |

Electric data

|

Mold |

Axial Fans |

Electric Defrost |

||||||||

|

Diameter(∮mm) |

N⁰ |

Voltage(V,50/60Hz) |

Power(W) |

Current(A) |

Air Flow (m³/h) |

Throw(m) |

Coil(W) |

Drain Pan (W) |

Total(W) |

|

|

FHKT 3001 05 10D |

300 |

1 |

~220 |

87/105 |

0.44/0.48 |

2030 |

9 |

2x570 |

1x570 |

1710 |

|

FHKT 3001 07 10D |

300 |

1 |

~220 |

87/105 |

0.44/0.48 |

1860 |

8 |

2x570 |

1x570 |

1710 |

|

FHKT 3002 10 10D |

300 |

2 |

~220 |

174/210 |

0.88/0.96 |

4060 |

11 |

2x1030 |

1x1030 |

3090 |

|

FHKT 3002 15 10D |

300 |

2 |

~220 |

174/210 |

0.88/0.96 |

3720 |

10 |

2x1030 |

1x1030 |

3090 |

|

FHKT 3003 15 10D |

300 |

3 |

~220 |

261/315 |

1.32/1.44 |

6090 |

13 |

2x1500 |

1x1500 |

4500 |

|

FHKT 3003 22 10D |

300 |

3 |

~220 |

261/315 |

1.32/1.44 |

5580 |

12 |

2x1500 |

1x1500 |

4500 |

|

FHKT 3004 20 10D |

300 |

4 |

~220 |

348/420 |

1.76/1.92 |

8120 |

15 |

2x2000 |

1x2000 |

6000 |

|

FHKT 3004 29 10D |

300 |

4 |

~220 |

348/420 |

1.76/1.92 |

7440 |

14 |

2x2000 |

1x2000 |

6000 |

Selection Diagram

FHKT 10/D Series

-

Ice Making Condensing Units are essential devices in commercial and industrial ice production. They play a critical role in efficiently converting wat...

READ MORE -

The car air conditioner evaporator is a crucial component in the vehicle's air circulation system, and its replacement involves refrigerant handling a...

READ MORE -

In refrigeration system design, the capacity matching of the condensing unit is crucial, directly affecting the system's energy efficiency and lifespa...

READ MORE -

Evaporator scaling is a common problem in industrial refrigeration and automotive air conditioning systems. Scaling not only affects heat transfer eff...

READ MORE

Overview

1. Industry Overview

The compact FHKT evaporator is a specialized refrigeration component designed for efficient heat exchange in compact spaces. These evaporators are particularly suited for applications where space is limited, such as in commercial refrigeration units, cold storage facilities, and smaller HVAC systems. Their design ensures effective cooling performance while maximizing available space.

2. Market Demand

- Growing Need for Space-Efficient Solutions: As urbanization continues and available space in commercial and residential settings decreases, there is an increasing demand for compact refrigeration solutions that deliver high performance without requiring extensive installation space.

- Focus on Energy Efficiency: Businesses and consumers are prioritizing energy-efficient systems that can lower operational costs, driving the adoption of advanced evaporator technologies that minimize energy consumption while maintaining optimal cooling.

- Diverse Application Needs: The compact design of FHKT evaporators allows them to be integrated into a variety of settings, including small restaurants, convenience stores, and mobile refrigeration units, making them versatile solutions in the market.

3. Product Features

- Space-Saving Design: The compact nature of the FHKT evaporator allows for easy installation in tight spaces, making it an ideal choice for locations with limited room for traditional evaporators.

- Efficient Heat Transfer: These evaporators are engineered to optimize airflow and refrigerant distribution, enhancing heat exchange efficiency and ensuring consistent cooling performance.

- Durability: Constructed from high-quality materials, compact FHKT evaporators are built to withstand demanding operational conditions, ensuring longevity and reliable performance over time.

4. Applications

- Commercial Refrigeration: Commonly used in small-scale refrigeration systems such as display cases, under-counter refrigerators, and walk-in coolers, providing effective cooling in limited spaces.

- HVAC Systems: Integrated into compact HVAC units, these evaporators help maintain comfortable indoor environments in both residential and commercial settings.

- Food Service: In restaurants and cafes, compact FHKT evaporators are used to keep food and beverages at safe temperatures while maximizing kitchen space efficiency.

5. Future Development Trends

- Integration of Smart Technologies: The trend towards smart refrigeration systems is expected to grow, with innovations allowing for enhanced monitoring and control of evaporator performance, contributing to energy savings and operational efficiency.

- Sustainability Initiatives: There is a strong focus on developing eco-friendly refrigerants and energy-efficient designs that align with global sustainability goals and regulations.

- Modular Designs: Future advancements may include modular compact evaporators that offer flexibility in configuration, allowing users to customize systems based on specific cooling needs.

EN

EN

English

English русский

русский Español

Español

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600