Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

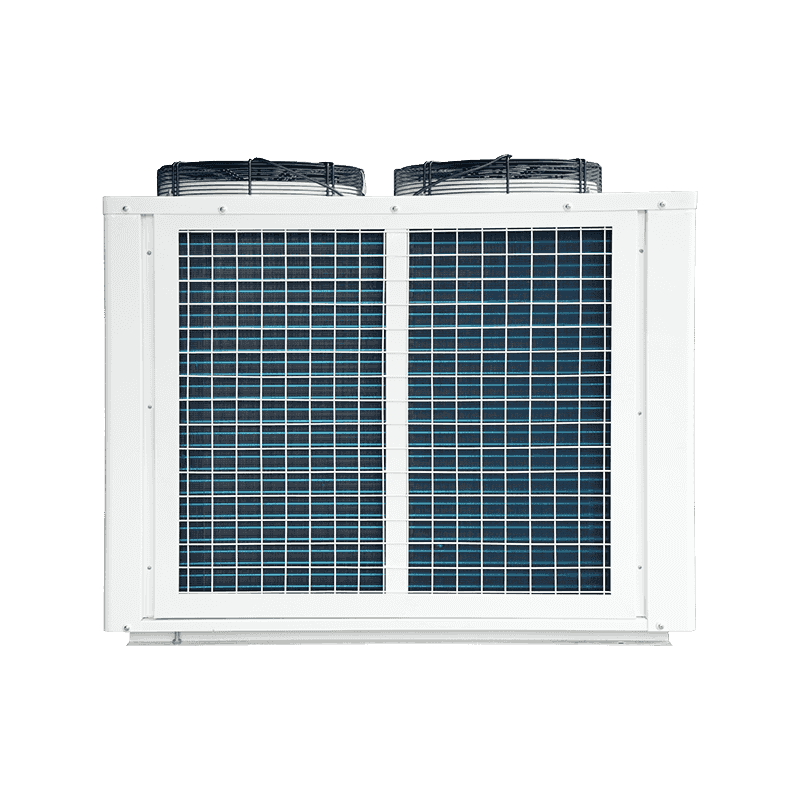

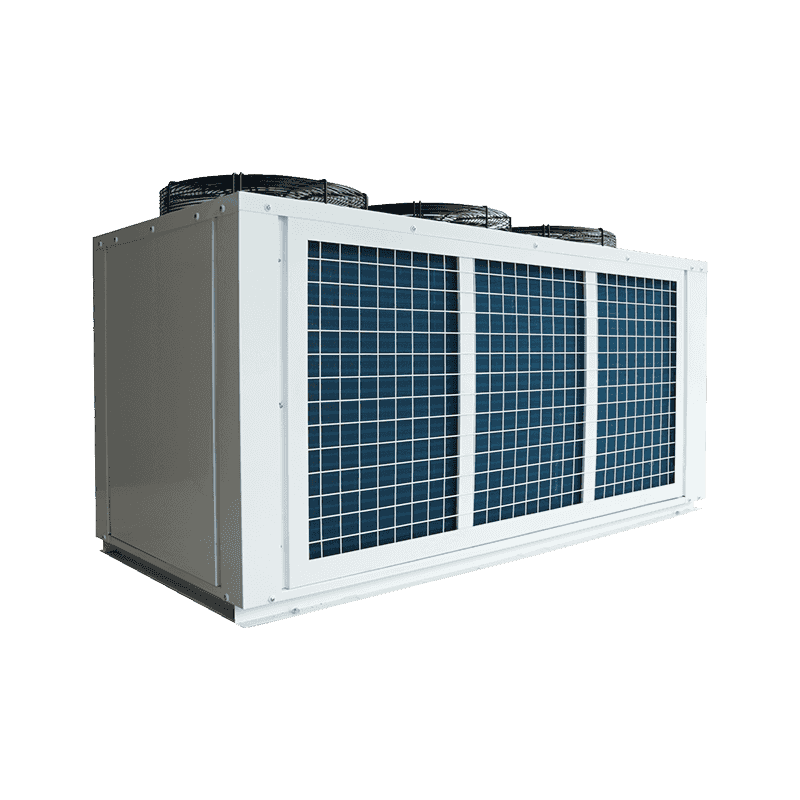

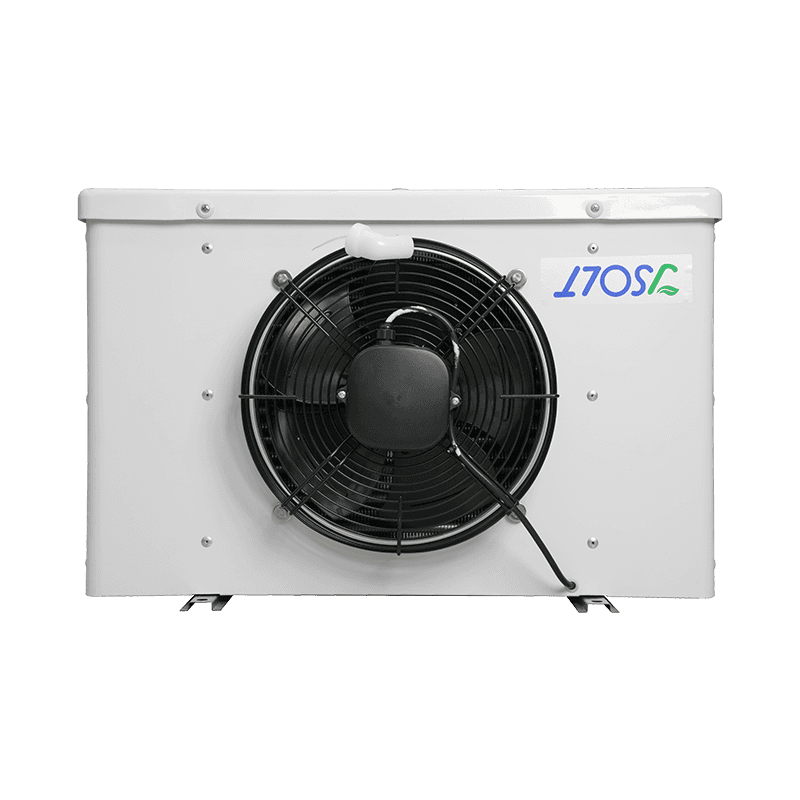

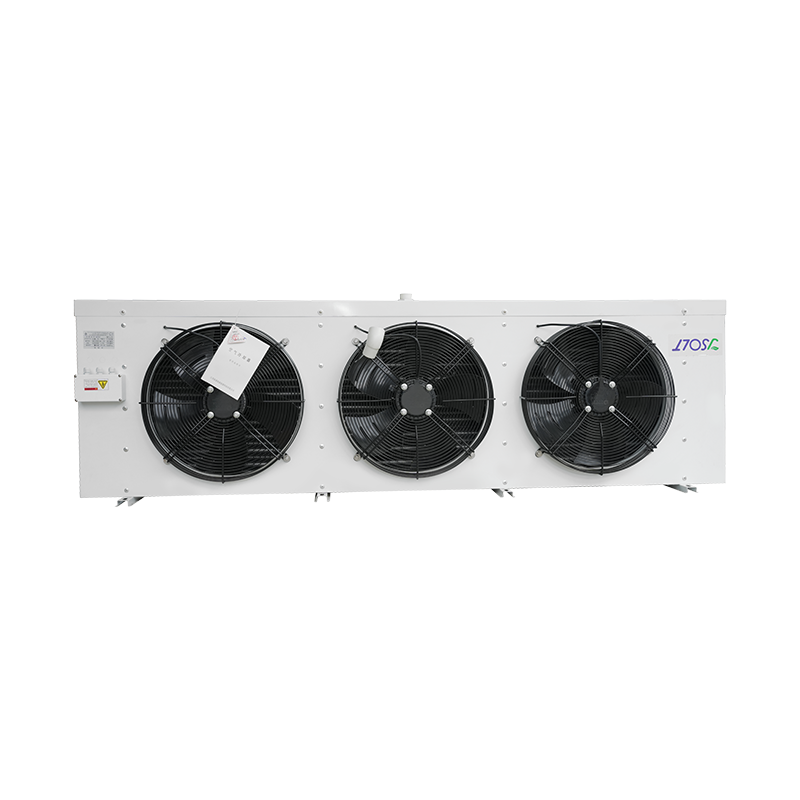

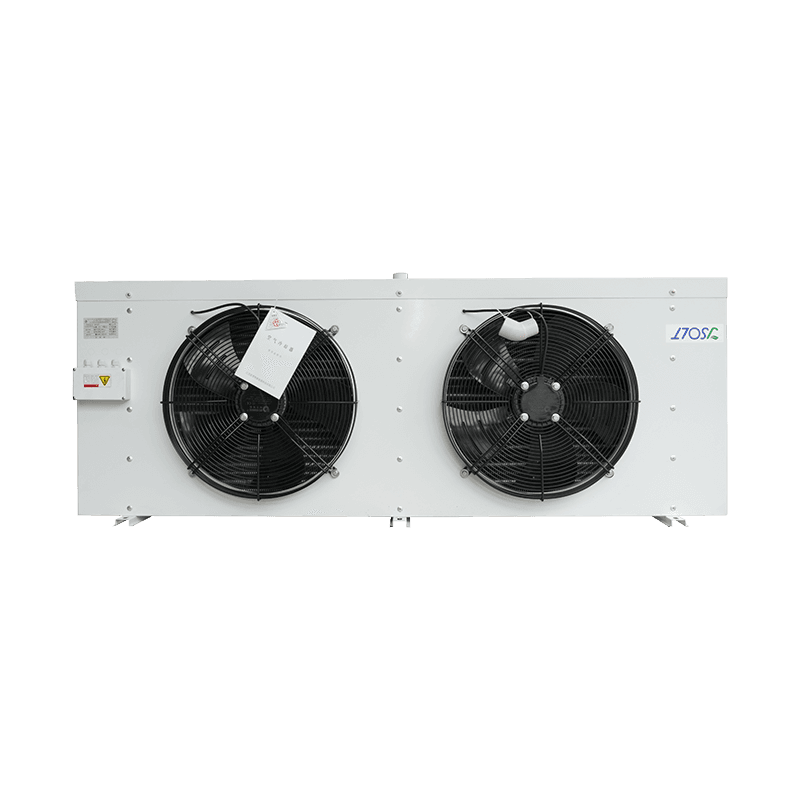

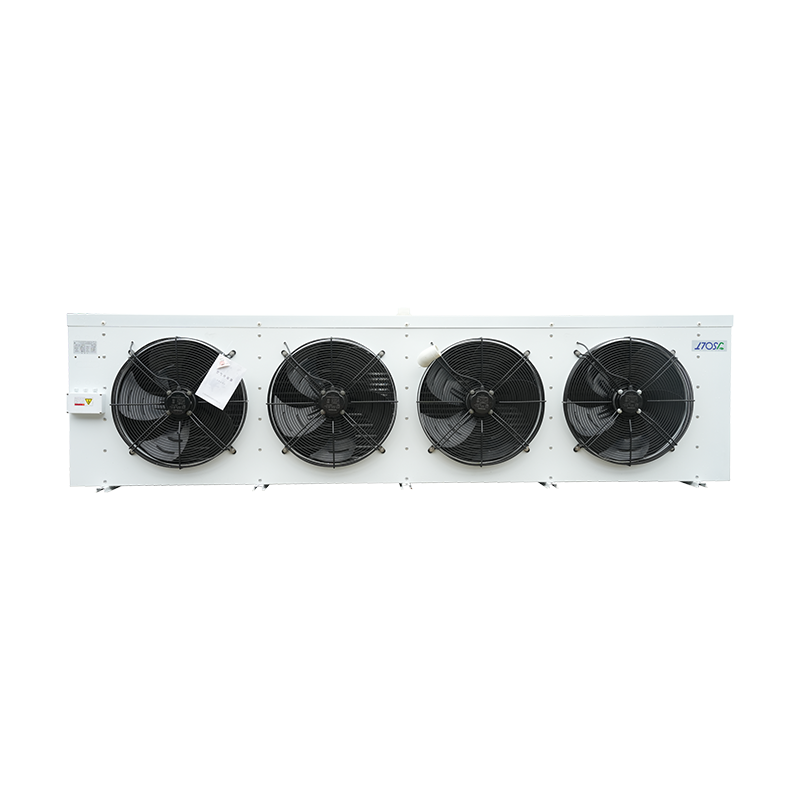

Will the shell of the high efficiency air cooler generate polluting debris?

As a key component in the industrial cooling system, the design and material selection of the shell of the high efficiency air cooler are crucial to the overall performance, durability and environmental adaptability of the equipment. The shell is made of white powder-coated aluminum. There are many considerations behind this decision, which is aimed at ensuring that the equipment maintains efficient, stable and environmentally friendly operation in a complex and changing working environment.

The powder coating is evenly covered on the surface of the aluminum substrate through electrostatic spraying technology, and then cured at high temperature to form a dense and continuous coating. This process ensures strong adhesion between the coating and the aluminum substrate, effectively preventing the coating from peeling off or producing fragments. The coating has a non-porous structure and can effectively resist external erosion such as moisture, salt, and pollutants, further enhancing the durability and integrity of the shell.

Aluminum itself has good corrosion resistance, and powder coating further enhances this feature. Even in harsh industrial environments, such as high humidity, high salt or corrosive gases, the shell can remain intact for a long time, reducing performance degradation or damage caused by corrosion.

The powder-coated aluminum housing has high hardness and toughness, can withstand a certain degree of physical impact and wear, and is not prone to scratches or dents, thus extending the service life of the equipment. During daily operation and maintenance, even if it occasionally encounters collisions or friction, the housing can maintain its integrity and avoid debris that may pollute the environment.

Powder coating is an environmentally friendly coating that does not contain harmful solvents, heavy metals or other harmful substances, and is harmless to the environment and human health. During production and application, powder coating produces almost no volatile organic compounds (VOCs) emissions, which meets the requirements of modern industry for green and sustainable development.

The white powder coating not only gives the housing a simple and beautiful appearance, but also helps to reflect sunlight and heat, reduce the operating temperature of the equipment, and improve energy efficiency. The coating surface is smooth and flat, easy to clean and maintain, and reduces performance degradation and increased energy consumption caused by dust or dirt.

The white powder-coated aluminum housing of the high efficiency air cooler ensures the stable operation of the equipment in a complex and changeable industrial environment with its excellent durability, corrosion resistance, wear resistance, environmental protection, and beautiful and easy maintenance characteristics, while reducing potential pollution to the environment, reflecting the high level of modern industrial cooling technology and the sense of responsibility for environmental protection.

←

What are the key factors to pay attention to when installing the LKPG Series Refrigeration Condensing Unit?

→

Are commercial condensing units suitable for all types of commercial refrigeration equipment?

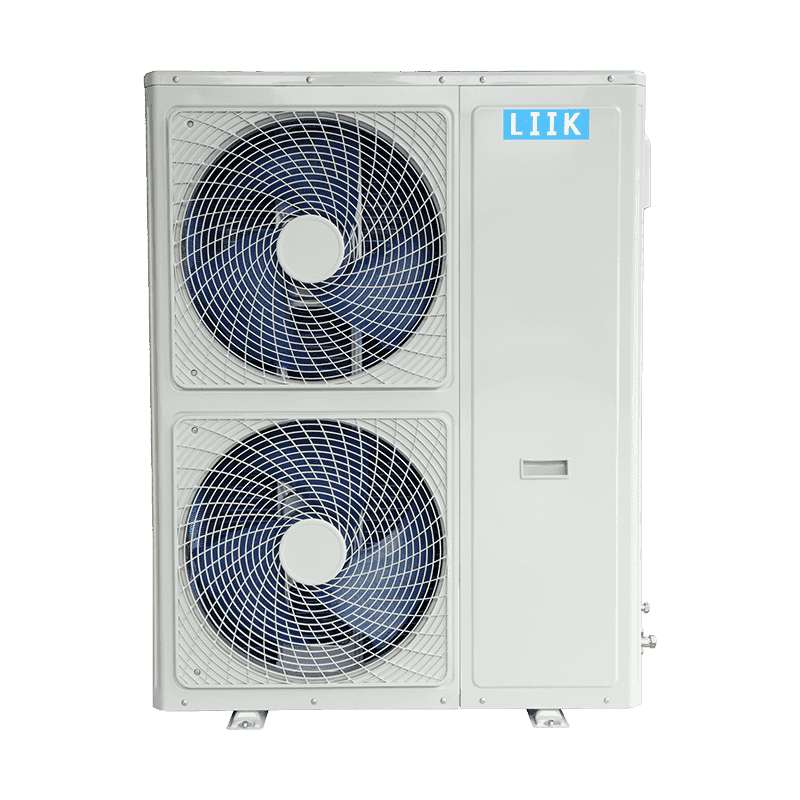

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español