Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

What are the different types of ice machines?

Different Types of Ice Makers

Ice makers can be classified by ice shape, application, and refrigeration method. The most common categories are:

| Type | Typical Ice Shape | Main Application Scenarios |

| Flake Ice Machine | Cylindrical, square, moon‑shaped flakes | Medical, fisheries, rapid food cooling |

| Plate Ice Machine | Thin flat plates | Supermarket fresh‑food display, quick food cooling |

| Sheet Ice Machine | Large‑area flat sheets | Large‑scale refrigeration, concrete cooling |

| Tube Ice Machine | Tubular ice with good storage and heat‑dissipation properties | Food refrigeration, industrial cooling |

| Shell Ice Machine | Encapsulated ice blocks | Cold‑chain logistics, vaccine transport |

| Snowflake Ice Machine | Snow‑flake‑like fine ice particles | Restaurant hot‑pot, Japanese cuisine plating |

| Scale Ice Machine | Scale‑shaped ice, low‑temperature rapid cooling | Large‑scale fresh‑food preservation, concrete cooling |

| Cube Ice Machine | Square or cubic ice blocks | Hotels, restaurants, beverage cooling |

These classifications meet a wide range of needs from small household units to large industrial installations. Taizhou Best provides corresponding OEM/ODM solutions based on these market segments.

How does an ice maker work?

Working Principle of an Ice Maker

The core of an ice maker is the refrigeration cycle, which consists of a compressor, condenser, expansion valve, and evaporator. The cycle proceeds as follows:

1.Compression – The compressor pressurizes the refrigerant into a high‑temperature, high‑pressure gas.

2.Condensation – The hot gas passes through the condenser, releases heat, and condenses into a high‑pressure liquid.

3.Expansion – The liquid refrigerant flows through an expansion valve, dropping in pressure and temperature, becoming a low‑temperature, low‑pressure mixture.

4.Evaporation – The low‑temperature refrigerant enters the evaporator (or ice bucket), absorbs heat from the water, lowering the water temperature below the freezing point and forming ice.

5.Ice Formation & Discharge – Once ice forms, gravity or an automatic release mechanism drops the ice into a storage bin, completing one ice‑making cycle.

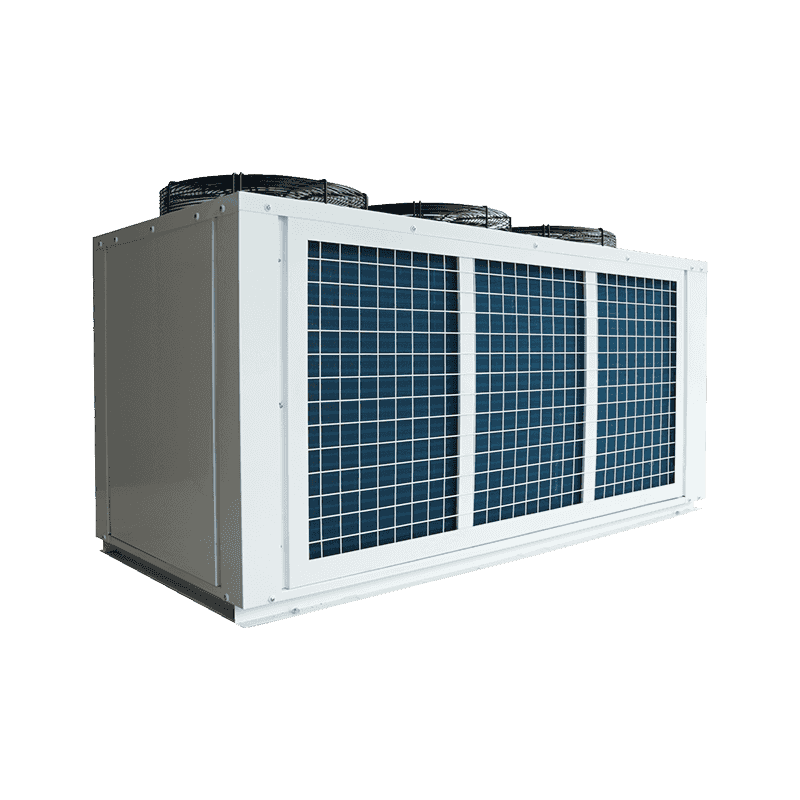

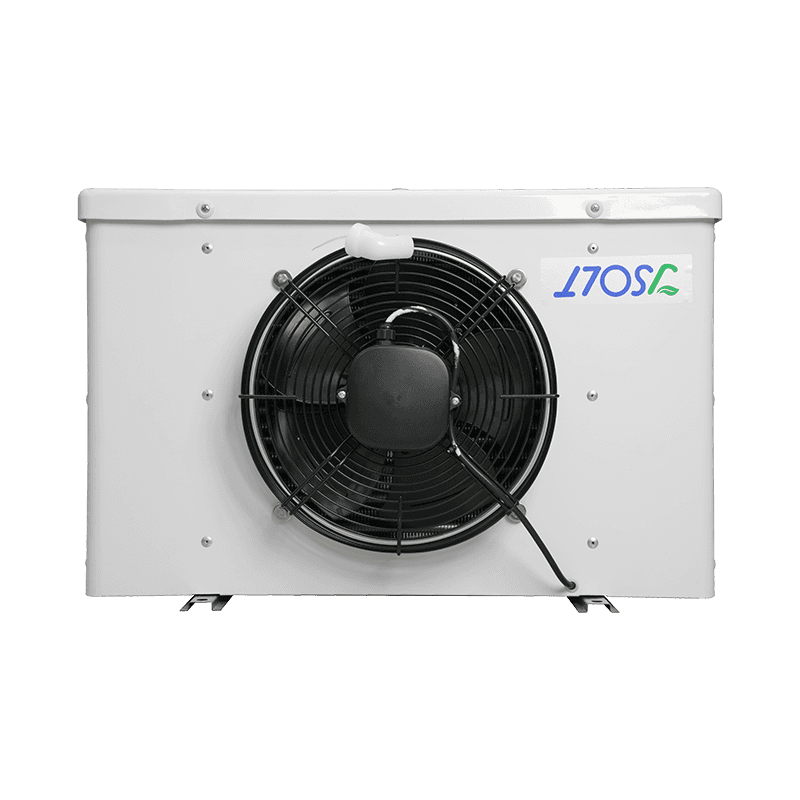

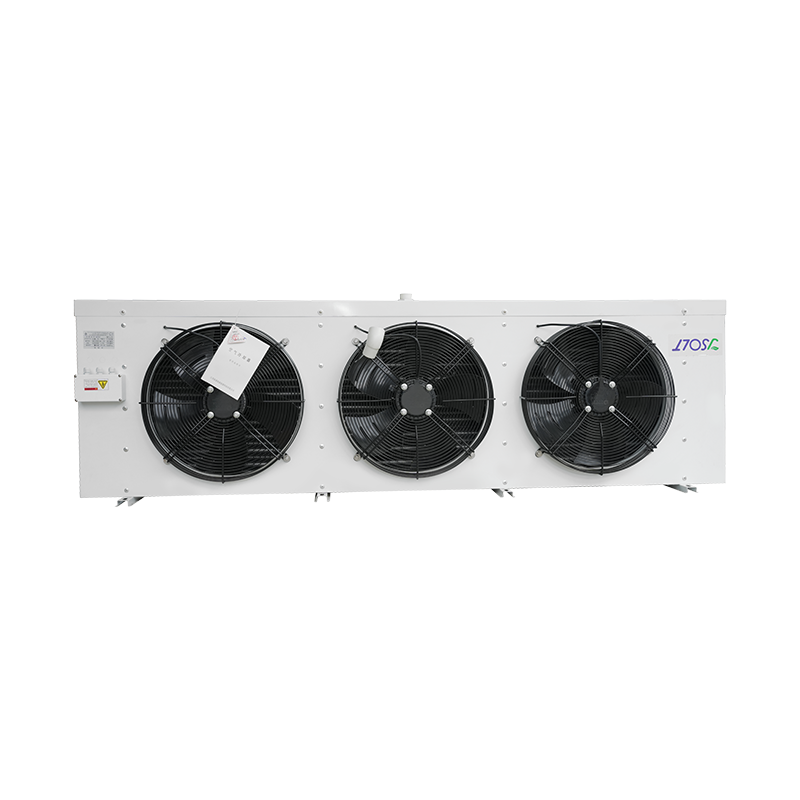

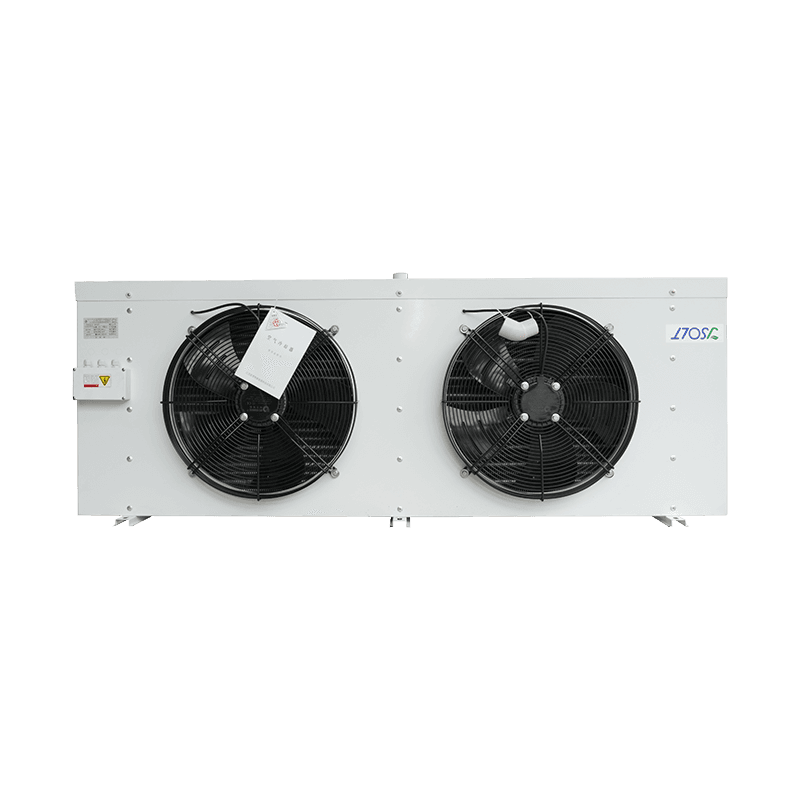

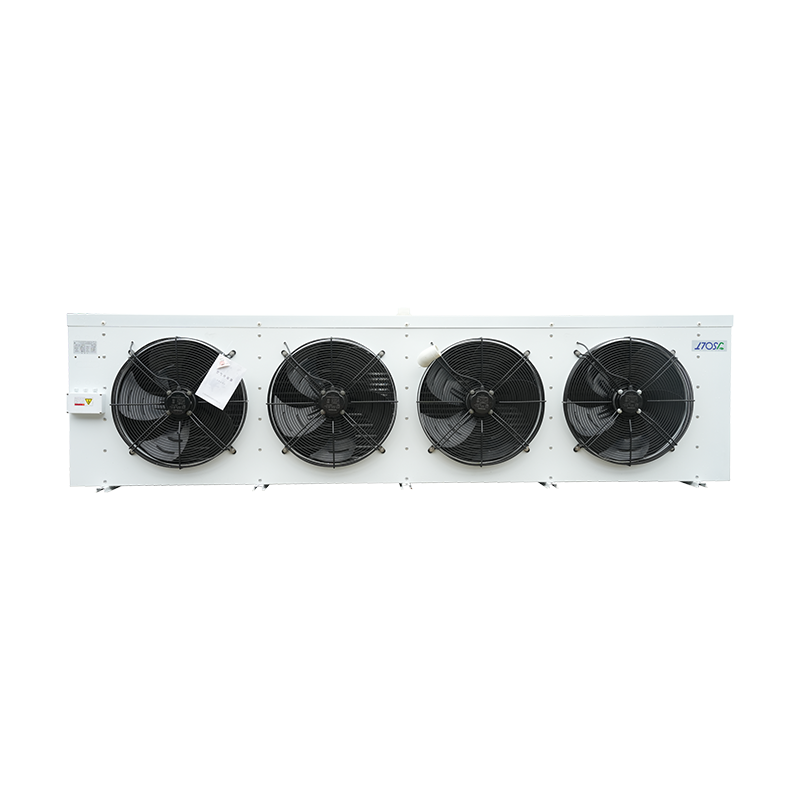

Different models have specific variations. For example, plate ice machines use a water‑curtain spray to create a thin water film that freezes rapidly on the evaporator surface; tube ice machines employ tubular cooling surfaces to improve efficiency. Taizhou Best’s refrigeration and condensation units use high‑efficiency compressors and precise temperature‑control systems, ensuring stable operation across the ¼ hp to 100 hp range and supporting the production of various ice shapes.

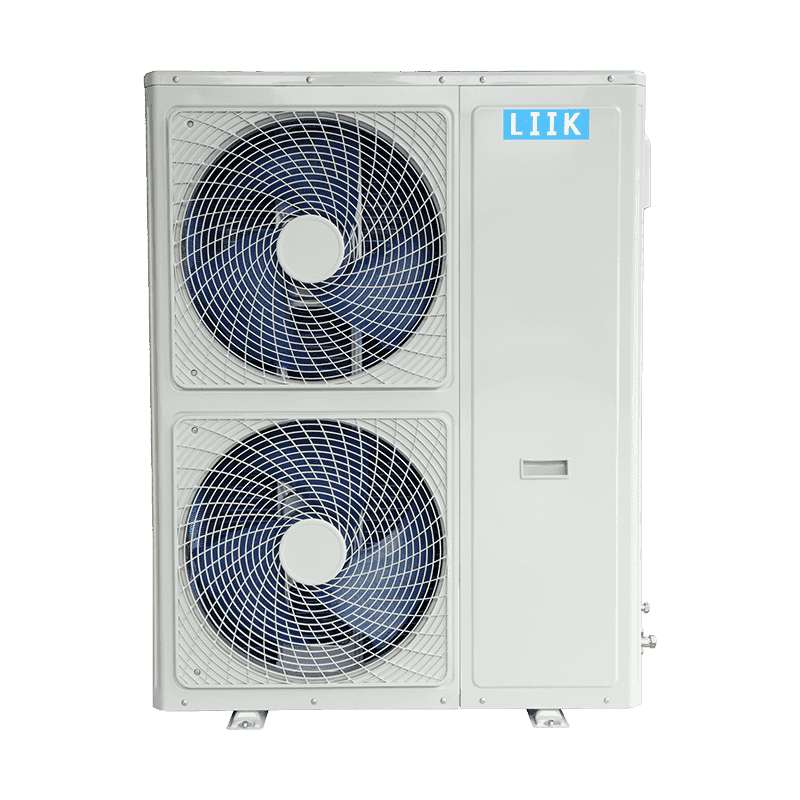

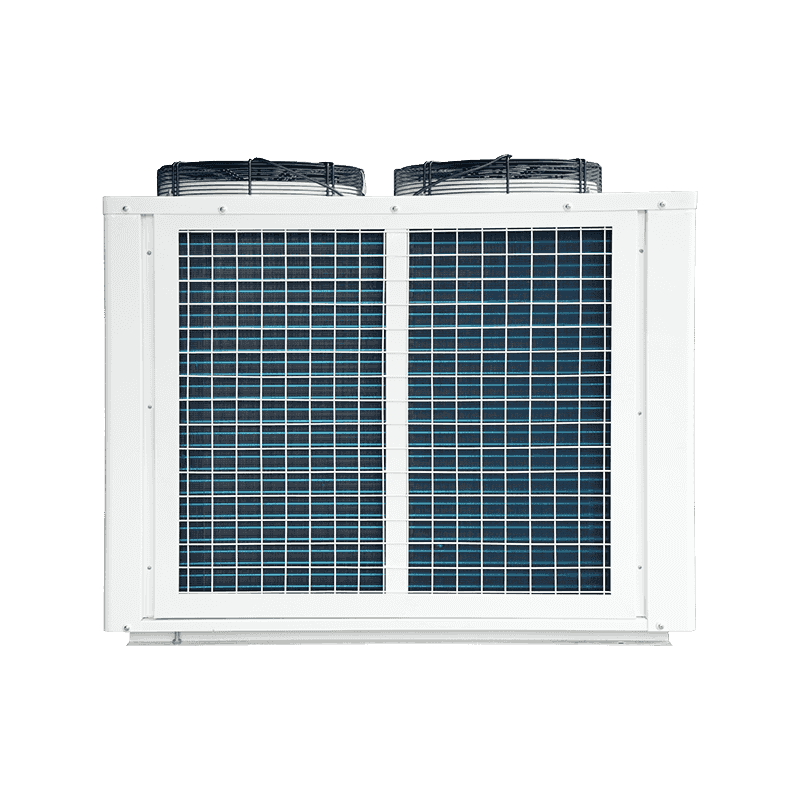

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español