Product Series

-

Ice Making Condensing Units are essential devices in commercial and industrial ice production. They play a critical role in efficiently converting water into ice while maintaining energy efficiency an...

READ MORE -

The car air conditioner evaporator is a crucial component in the vehicle's air circulation system, and its replacement involves refrigerant handling and precise disassembly and assembly. The following...

READ MORE -

In refrigeration system design, the capacity matching of the condensing unit is crucial, directly affecting the system's energy efficiency and lifespan. The following are key indicators for determinin...

READ MORE

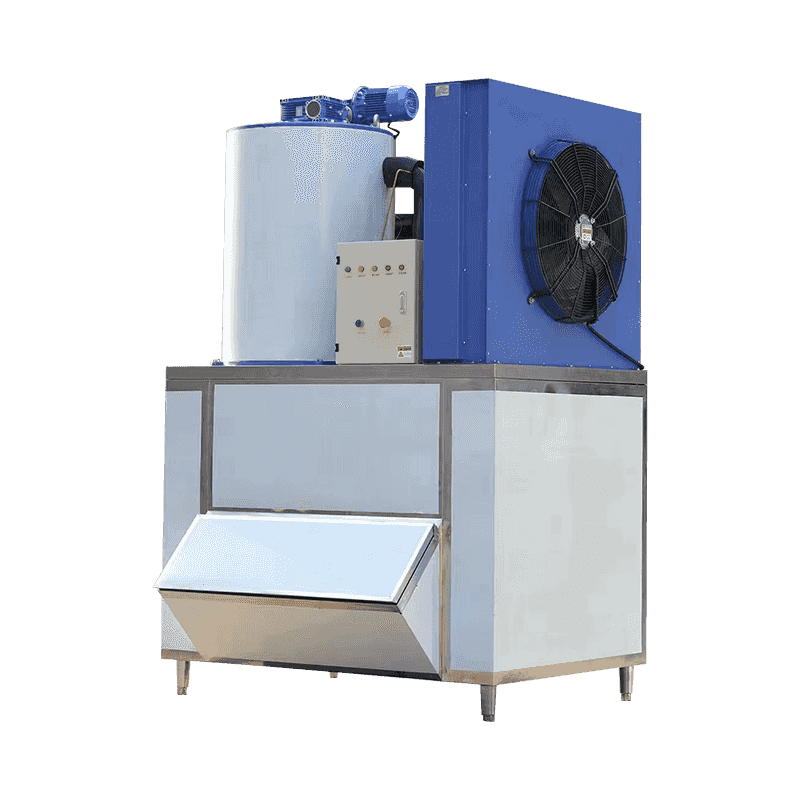

Ice Making Condensing Units are a vital component in the ice making system. Their main function is to condense the high-temperature and high-pressure gas generated by the refrigerant after absorbing heat in the evaporator, converting it into a high-pressure liquid, thereby releasing heat and providing the necessary conditions for the subsequent refrigeration cycle.

The Ice Making Condensing Units produced by Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd are widely used in various places where ice making is required, such as food processing plants, beverage production lines, seafood preservation warehouses, hospitals, schools, restaurants, etc. They provide stable and efficient ice making solutions for these places, meeting the needs of ice quality and quantity in different fields. We have rich industry experience and deep technical strength. We are committed to providing customers with high-quality and high-performance refrigeration equipment and services to meet the needs of refrigeration technology in different fields.

Our Ice Making Condensing Units use efficient compressors and condensers, which can quickly transfer the heat in the refrigerant to the external environment, thereby ensuring the efficient operation of the ice maker. Equipped with multiple safety protection devices inside, such as overload protection, high and low pressure protection, etc., it can operate stably under various harsh conditions to ensure the continuity and stability of the ice making process. Reasonable design, compact structure, easy for daily maintenance and servicing.

In order to ensure the stable operation and extend the service life of the ice machine condensing unit, regular maintenance and servicing are required. This includes cleaning the condenser surface, checking the refrigerant pressure and temperature, replacing worn parts, etc. At the same time, it is also necessary to avoid using the ice machine under harsh environmental conditions to reduce damage to the condensing unit.

EN

EN

English

English русский

русский Español

Español

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600