Web Menu

Product Search

Exit Menu

Product categories

News categories

RECENT POSTS

-

What are the main components of Ice Making Condensing Units?

Jan 09,2026 -

How to replace a broken car air conditioner evaporator?

Jan 02,2026 -

How to determine if the condensing unit capacity selection is appropriate?

Dec 26,2025 -

Why does the evaporator always scale up?

Dec 19,2025 -

What are the commonly used refrigerants in a Refrigeration System and their applicable ranges?

Dec 12,2025

How does an anti-frost heater work and what environmental conditions are suitable for it?

Working Principle

Heating Elements:

Material and Design: Anti-frost heaters usually use stainless steel heating elements, which are corrosion-resistant, high-temperature-resistant and can effectively conduct heat. The heating elements are designed to fit tightly with the cooler's aluminum fins or drain pan to ensure even heat transfer.

Heating Area: The heating elements are distributed within the fin group and on the drain pan of the J3 high efficiency air cooler. This allows the device to be heated from multiple angles to prevent frost from forming.

Temperature Control System:

Temperature Sensor: Anti-frost heaters are usually equipped with temperature sensors that can monitor the ambient temperature in real time. When the temperature drops to a set threshold (such as 0°C or lower), the temperature control system automatically activates the heating element.

Intelligent Control: Some advanced systems are equipped with a microprocessor control unit that can intelligently adjust the heating intensity according to environmental changes to achieve energy saving.

Anti-frost working mechanism:

Heat conduction: When the heating elements are powered on, they quickly generate heat, which is transferred to the surrounding air and cooler surface through the heat-conducting material to prevent frost.

Moisture evaporation: While heating, the moisture on the surface of the J3 high efficient air cooler is heated and evaporated, preventing the moisture from condensing into frost in a low temperature environment. This keeps the equipment clean and running efficiently.

Applicable environmental conditions

Low temperature environment:

Refrigeration and freezing: The anti-frost heating device is very suitable for use in environments such as cold storage, frozen warehouses and low-temperature production lines. In these places, the temperature may drop below freezing, and the anti-frost device can ensure the normal operation of the J3 high efficient air cooler and prevent frost from affecting air circulation and cooling effects.

Humid environment:

Humidity control: In high humidity environments, such as coastal areas, certain agricultural uses or aquatic product processing sites, the anti-frost heating device can effectively prevent moisture from condensing on the cooler surface, thereby reducing maintenance frequency and the risk of equipment failure.

Places with frequent temperature fluctuations:

Climate change: In areas with frequent climate changes, the external temperature may fluctuate violently. The anti-frost heating device can ensure that the cooler maintains efficient operation at different ambient temperatures and reduce performance degradation caused by temperature fluctuations.

Industrial and Commercial Uses:

Food Processing: In the food processing industry, temperature and humidity control is crucial, and anti-frost heaters ensure the efficiency of cooling equipment to avoid affecting food quality.

Air Conditioning and Ventilation Systems: In air conditioning and ventilation systems in large buildings or commercial premises, anti-frost heaters help maintain system efficiency and extend equipment life.

←

What are the characteristics of the scroll and reciprocating compressors available for 20 Horses Commercial Condensing Units?

→

What are the advantages and disadvantages of different types of condensers?

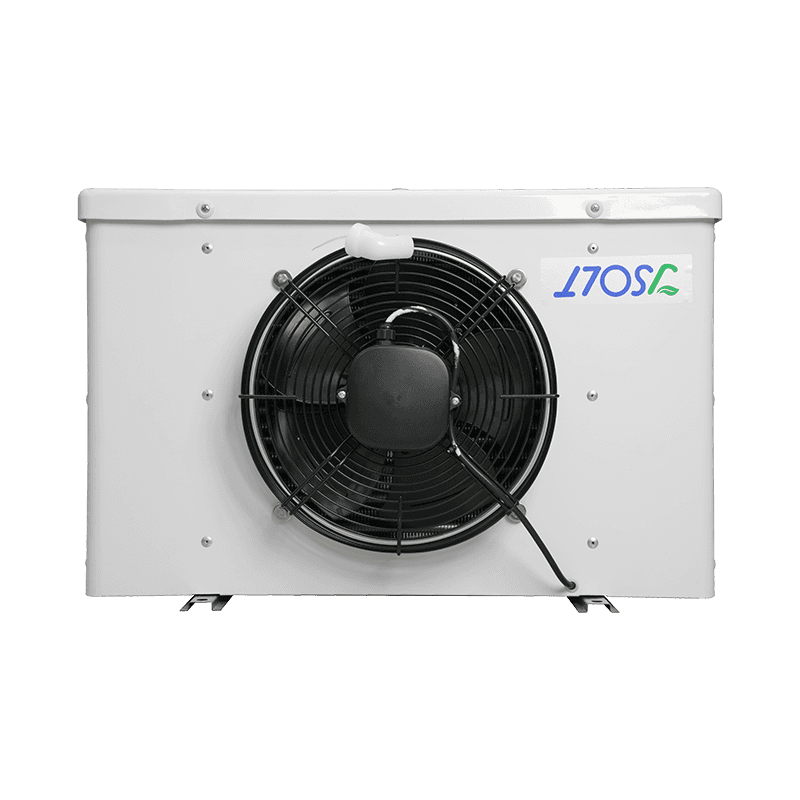

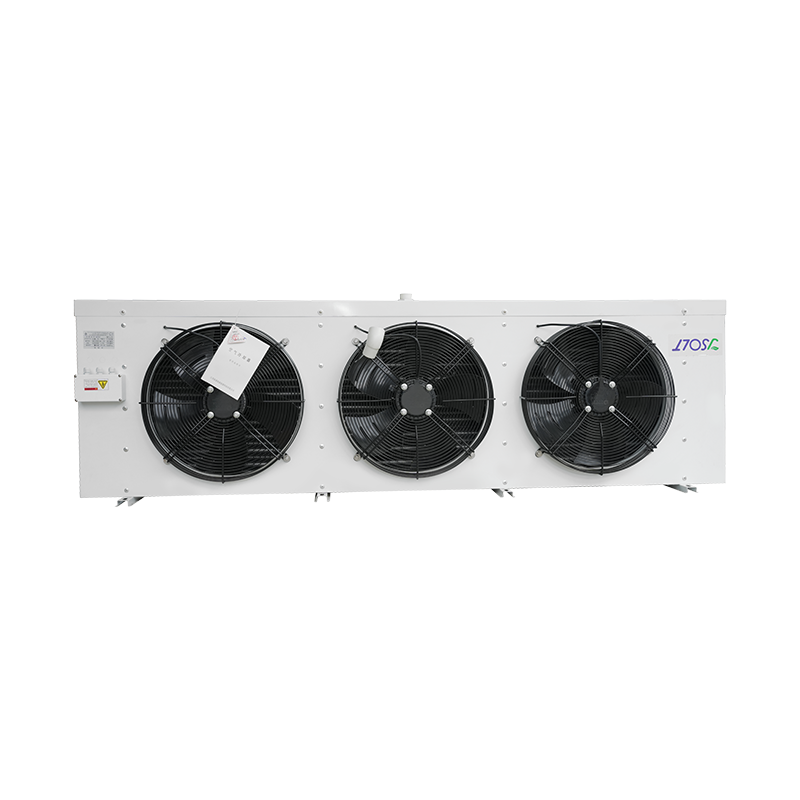

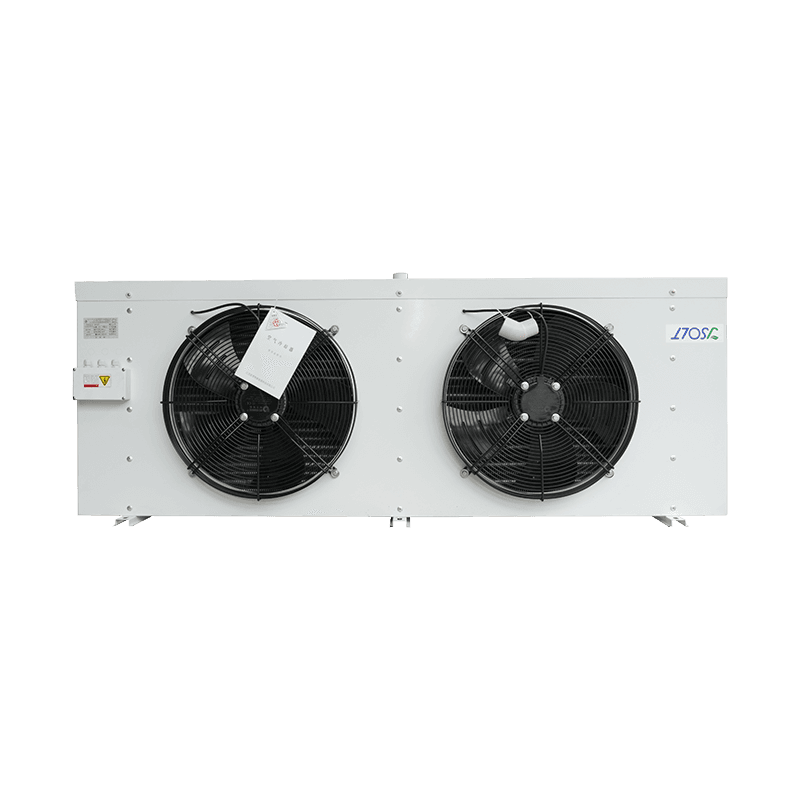

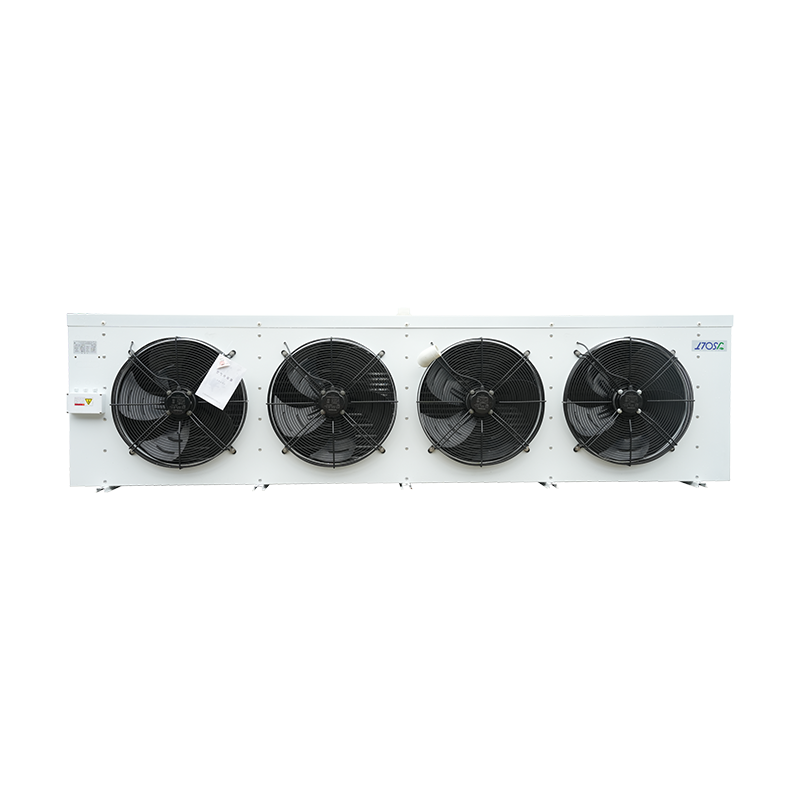

related products

-

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province

224 Yongping Road, Science and Technology Enterpreneurship Park, Gaogang District, Taizhou City, Jiangsu Province  +86-18082061600

+86-18082061600 [email protected]

[email protected]

Copyright © 2024 Taizhou Best Refrigeration Equipment Manufacturing Co., Ltd All Rights Reserved. Refrigeration Equipment Manufacturer Custom Refrigeration Equipment Factory

EN

EN

English

English русский

русский Español

Español